Tannin-based coagulants application in the food processing industry

DOWNLOAD THE PAPER

Abstract

This study evaluates the performance of an organic coagulant derived from tannins sourced from Acacia tree bark in wastewater treatment. The environmental impact of the coagulant is examined, along with its effectiveness in TSS and nutrient removal. The implementation of the organic coagulant is assessed for its environmental implications, including carbon sequestration potential through forest establishment.

The coagulant demonstrates efficiency in TSS removal, with promising results observed across different dosing concentrations. Additionally, its capacity for nutrient removal, particularly nitrogen and phosphorus, is investigated. The study explores the coagulant’s potential to reduce aeration requirements in the wastewater treatment process, aiming to identify opportunities for energy savings and environmental conservation. The coagulant’s applicability across various industries is considered, with implications for wastewater treatment practices and sustainability efforts.

The findings suggest that the organic coagulant holds promise as a sustainable solution for wastewater treatment. Further research is needed to evaluate its broader effectiveness and potential benefits in diverse wastewater scenarios.

Introduction

In the dynamic landscape of wastewater treatment, organic coagulants derived from natural sources are gaining attention for their potential in various industrial sectors. Tanfloc, an organic coagulant derived from tannins found in Acacia tree bark, has gained traction, especially within industries such as red meat processing. Over recent years, there has been growing interest in exploring alternatives to traditional metal-based coagulants, with a focus on enhancing pre-treatment efficiency, particularly in Dissolved Air Flotation (DAF) processes.

Tanfloc offers a promising solution to address key challenges in wastewater treatment, including the removal of Total Suspended Solids (TSS), Oil and Grease (O&G), and Nitrogen (N). Its application has shown potential for improving operational processes by reducing equipment corrosion and simplifying maintenance activities. There is also growing recognition of the environmental benefits associated with Tanfloc, with efforts made to promote carbon negativity through initiatives such as extensive planted forests.

This introduction aims to explore the evolving landscape of organic coagulants in wastewater treatments, focusing on their role in addressing treatment challenges, promoting environmental responsibility, and offering sustainable solutions for water management.

Background

Coagulation/Flocculation

Coagulation and flocculation are essential processes in water treatment, particularly for addressing turbidity, a crucial indicator of water quality. High turbidity in water can pose challenges for disinfection and render it unsuitable for various applications, such as irrigation. Turbidity often arises from the presence of suspended particles, named colloids, which remain dispersed in water for extended periods of time, complicating water pollution management.

Colloids possess the ability to absorb ions and carry an electric charge. In water, these colloids typically exhibit negative charges, causing them to repel each other and remain dispersed in the liquid phase. Coagulants are usually positively charged chemicals, so they attract and neutralise the negatively charged colloids, reducing their zeta potential. This reduction in electrical surface charge means that Van Der Waals attractive forces between particles dominate, and the colloids aggregate into larger particles.

Various types of coagulants are employed in wastewater treatment, including metal-based, synthetic, and biopolymer coagulants, but can be broadly classified into inorganic and organic coagulants. Organic coagulants can assist coagulation through mechanisms such as charge destabilisation and chemical bridging, while inorganic coagulants are capable of charge destabilisation and sweep flocculation. Advantages of organic coagulants include their ability to perform charge destabilisation at all pH ranges and are also able to perform chemical bridging while doing so. This means that the required dosage for coagulation to occur is ten times smaller for organic coagulants when compared to inorganic coagulants.

Following coagulation, the process of flocculation ensues. Flocculation involves the assembly of primary particles into larger agglomerates called flocs, aiding the removal of suspended particles through filtration or decantation.

The effectiveness of flocculation can be enhanced with the addition of flocculants. These chemicals adsorb onto the coagulated particles, modifying their surface charges and bridging gaps to facilitate floc formation. By bringing particles into proximity, flocculants reduce the energy barrier for flocculation, enabling the formation of larger, visible macro flocs. Sedimentation of these macro flocs ensures efficient solid-liquid separation.

As discussed, coagulants assist coagulation/flocculation through various mechanisms. The mechanism employed is highly dependent on the nature of the coagulant, dosage rate, pH of the operating environment, and the nature of colloidal particles in water. Seen below is a summary of the most common mechanisms employed by coagulants. Figure 1 shows a graphical illustration of each mechanism described.

Figure 1: Mechanisms of coagulation and flocculation (Suopajärvi, 2015)

Figure 1: Mechanisms of coagulation and flocculation (Suopajärvi, 2015)

Charge neutralisation

This mechanism is commonly observed and involves positively charged coagulants neutralising negatively charged colloids, which enables their aggregation through Van Der Waals forces. Both organic and inorganic coagulants are capable of charge destabilisation, but, with their longer chain length, organic coagulants can also utilise charge patch neutralisation for coagulation, which involves an organic coagulant attaching to the surface of a colloid, giving the colloid a positively charged ‘patch’. This forms a mosaic surface used for attracting and entrapping other particles.

Sweep flocculation

Primarily associated with inorganic coagulants, sweep flocculation relies on the formation of solid hydroxide precipitates, such as metallic hydroxide flocs. These precipitates entrap colloidal particles within floc structures, leading to the formation of larger flocs. In contrast, organic coagulants do not participate in sweep flocculation, as they are typically unable to form solid hydroxide precipitates.

Chemical bridging

This mechanism is unique to long-chain organic coagulants and involves the formation of threads or fibres that attach to multiple colloidal particles, forming a backbone for floc formation. Organic coagulants excel in charge destabilisation and chemical bridging, producing larger and stronger flocs compared to inorganic coagulants.

Importance of pH

The pH of the water is especially significant as it influences the effectiveness of coagulation mechanisms. Inorganic coagulants exhibit pH-dependent behaviour, with charge destabilisation predominant at a pH below five and sweep flocculation occurring at a pH above six. pH influences the zeta potential of colloidal particles, determining their stability. At the isoelectric pH, colloids have no zeta potential, and thus no repulsion between particles, allowing coagulation to occur.

pH also affects the ionisation of dissolved species in water, and the extent of ionisation of functional groups on turbid matter. For inorganic coagulants, such as aluminium, iron, magnesium and calcium, pH determines which ionic species are present and whether metallic hydroxide flocs will form. Different pH levels lead to the formation of various hydroxyaluminium complexes, which impact the coagulation process. At lower pH, positively charged hydroxyaluminium species destabilise particles’ zeta potential, promoting coagulation. At high pH, negatively charged hydroxyaluminium species can interfere with coagulation.

In contrast, organic coagulants maintain effectiveness across a broader pH range, making them versatile for water treatment applications. Their positive charge remains constant across all pH levels, allowing them to act as effective charge destabilisers and chemical bridging coagulants over a broader pH range.

Understanding the intricacies of coagulation and flocculation mechanisms is crucial for optimising the water treatment process, ensuring efficient removal of suspended particles, and safeguarding water quality for various applications.

Comparison of coagulants

Sludge volume

The treatment and disposal of both primary and secondary sludge from WWTP are important factors to consider in plant operation and design. The primary objectives of processing sludge before its disposal are reducing its volume, and stabilising organic components. When the sludge is stabilised, it poses minimal health risks. Decreasing the sludge volume aids in ease of disposal, and minimises expenses associated with pumping and storage. The coagulant dosage is a factor that can affect the quantity of sludge produced. At the optimum dosage of coagulant, larger flocs can form, which have improved sedimentation and enhanced filtration abilities, reducing the volume of sludge generated downstream. In addition, larger flocs typically have reduced water retention and dewater with ease. Their lower water content naturally reduces the volume of the sludge. A larger coagulant dose may result in denser flocs that are more difficult to separate, and, from a mass balance perspective, increase the overall volume of sludge. Dimantis et al. (2013) conducted a study regarding the treatment of sewage water and were able to deduce a relationship between coagulant dosage and sludge volume, stating that the volume of sludge produced is directly proportional to the coagulant dosage (V. Diamantis and Aivasidis, 2013).

As previously discussed, organic coagulants can perform charge destabilisation and chemical bridging simultaneously, meaning that the required dosage of organic coagulants is 10 times smaller than the dosage required for inorganic coagulants (Utilities), leading to the conclusion that the use of organic coagulants will result in a lower sludge volume compared to inorganic coagulants, thereby decreasing operational costs and aiding sludge disposal.

Wastewater salinity

Upon their addition to water, metal ions present in metal-based coagulants undergo rapid hydrolysis, forming a series of metal hydrolysis species (Bratby, 2006). Factors such as the pH and coagulant dosage determine the most suitable species for treatment, due to inorganic coagulants’ high dependence on pH. The metal hydroxide salts produced from the abode hydrolysis pose challenges regarding the use of treated wastewater. Often, the treated wastewater is used for farming and agricultural purposes, and there are salinity guidelines that the treated wastewater must be within, to maximise crop yield (Awad, 1984). Recommendations from the NSW Government, Department of Primary Industries, 1984, state that crops should accept salinity levels up to 385 mg/L. A recent study from the Australian dairy industry found that the use of Tanfloc as a flocculant revealed no increase in wastewater salinity, due to the organic coagulants inability to form hydroxide salts. In contrast, it was found that the use of aluminium sulphate as a coagulant increased the estimated salinity of the treated wastewater by ~ 33% (Hales, 2024). In addition to restricted irrigation uses, a high level of salinity may result in corrosion of equipment and pipes.

Carbon dioxide equivalent emissions

The carbon footprint and carbon dioxide equivalent (CO2-eq) emissions of inorganic and organic coagulants should be considered. A case study comparing the organic tannin-based coagulant with the inorganic coagulant aluminium sulphate was analysed (Bredemann, 2024). The coagulants carbon footprints were compared by calculating the carbon emissions (T. CO2 - eq/year) that will occur during production, transportation, and dewatering processes. Figure 2 displays a graphical representation of the numerical values of emissions from each product.

Figure 2: Tonnes of CO2 emitted across different boundaries (Bredemann, 2024)

Figure 2: Tonnes of CO2 emitted across different boundaries (Bredemann, 2024)

Figure 3 includes carbon dioxide emission data from other common metal-based coagulants, for comparison with Tanfloc.

Figure 3: Comparison of CO2-eq emissions of common coagulants (Bredemann, 2024)

It is evident that the cumulative emissions from the tannin-based coagulant were significantly less than that of aluminium sulphate. The percentage difference of emissions per ton of product was calculated to be ~ 79%. Similar differences were observed when comparing Tanfloc to polyaluminium chloride, ferric sulphate, ferric chloride sulphate, ferric chloride, and aluminium sodium hydroxide.

In addition to reduced total emissions associated with the use of the coagulant, the company behind Tanfloc achieved a positive Carbon Footprint by the plantation of 25,000 hectares of forests. BVQI verified that for every tonne of carbon dioxide equivalent emitted during production or use of the coagulant, six tonnes of CO2-eq are sequestered.

In summary, the comparison between Tanfloc and inorganic coagulants reveals significant differences in sludge volume, wastewater salinity, and carbon dioxide equivalent emissions. Organic coagulants, such as Tanfloc, require smaller doses, leading to reduced sludge volume and operational costs. Tanfloc’s inability to form hydroxide salts results in no increase in wastewater salinity, contrasting with the salinity issues associated with inorganic coagulants. Additionally, Tanfloc demonstrates substantially lower carbon dioxide equivalent emissions compared to inorganic coagulants, contributing to its positive Carbon Footprint.

Figure 4: Comparison of coagulants (Suopajärvi, 2015)

Figure 4: Comparison of coagulants (Suopajärvi, 2015)

Case studies

In recent years, the evaluation of water treatment technologies through case studies has become increasingly vital in understanding their practical applications and effectiveness in real-world scenarios. Case studies offer valuable insights into the performance and adaptability of these technologies, providing crucial data for decision-making in wastewater management practices. In this section, recent case studies of Tanfloc are presented, exploring its performance and applicability across diverse industrial settings (Tanafloc, 2024). Table 1 provides an overview of these case studies and showcases the dosage of Tanfloc, and the results observed in each study.

Table 1: Results of recent Tanfloc case studies

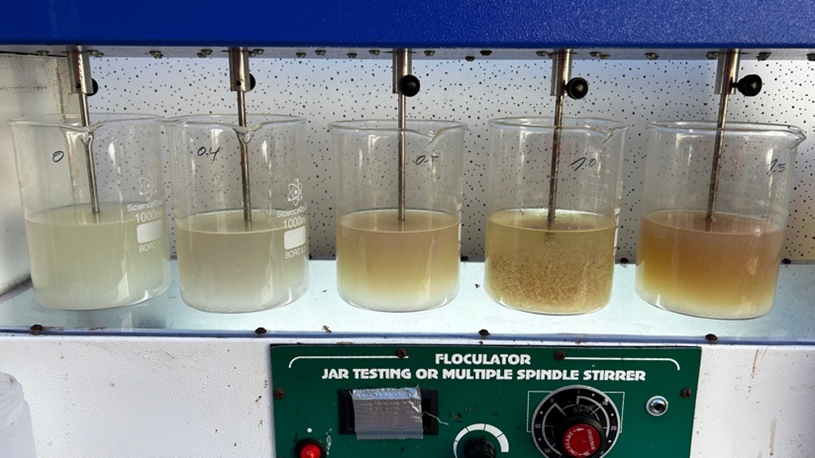

Figure 5 and Figure 6 show photographs taken from the dairy industry and red meat industry jar tests, after treating the wastewater samples with Tanfloc.

|

|

| Figure 5: Dairy industry jar test results | Figure 6: Red meat industry jar test results |

Method

The jar test methodology was utilised for the tests conducted at two red meat processing facilities and a dairy industry WWTP, aimed to assess the effectiveness of the tannin-based coagulant, Tanfloc. The methodology was structured to evaluate key parameters such as TSS removal, O&G reduction, N removal, and overall environmental impact.

The red meat processing plants in WA and NSW were strategically chosen to represent diverse operational conditions and environmental contexts. The additional study of a dairy industry WWTP also subjected the coagulant to more varied wastewater conditions, to determine the effectiveness of the Tanfloc in a wide range of operational contexts. Prior to the tests, the facilities underwent thorough assessments to establish baseline data on wastewater composition, pollutant levels, and existing treatment processes.

Tanfloc was introduced at full scale in the pre-treatment processes, specifically in DAF units, at both facilities. Real-time monitoring was employed to assess the coagulant’s performance in removing TSS, O&G, and N from the raw wastewater.

Comprehensive analyses were conducted to quantify the efficiency of Tanfloc in removing pollutants. This included assessing the reduction in TSS levels, O&G concentrations, and N content at various stages of the treatment process. Subsequent runs with lower dosing concentrations were conducted to evaluate the coagulants efficiency under varied conditions.

Nitrogen and phosphorus associated with solids were meticulously analysed to gauge Tanfloc’s effectiveness in nutrient removal. The study focused on understanding the coagulants’ role in addressing nutrient-related challenges in wastewater.

|

|

| Figure 7: Jar tests set up for red meat industry | Figure 8: Jar tests set up for dairy industry |

Results

The results from both jar tests and full-scale operations in two red meat processing facilities and the dairy industry demonstrated the impact of Tanfloc on wastewater treatment and environmental sustainability.

During jar tests, Tanfloc exhibited high efficiency in removing TSS, exceeding 90% in the initial run for both the red meat and dairy industry WWTP’s. High removal rates were maintained even at lower dosing concentrations. These findings were consistent with observations from full-scale operations, indicating Tanfloc’s effectiveness in clarifying wastewater compared to traditional metal-based coagulants.

Figure 9 shows the TSS removal efficiency versus dosing, for all effluents (WA and NSW red meat WWTP’s, and the WA dairy industry WWTP).

Figure 9: Turbidity and TSS removal using Tanfloc

Figure 10: Removal efficiency using the optimised dose of Tanfloc

Tanfloc displayed versatility in addressing nutrient-related challenges, with approximately 43% nitrogen and 23% phosphorus removal observed in preliminary treatment across both testing scales. Figure 10 shows the removal efficiency using the optimised dose of Tanfloc applied to raw wastewater.

Verification of a positive Carbon Footprint highlighted Tanfloc’s potential contribution to environmental sustainability, sequestering six tonnes of CO2e for every ton emitted. Reductions in aeration requirements, validated in both jar tests and full-scale operations, suggest potential cost savings in operational processes. Tanfloc’s success across diverse facilities indicates its applicability across various industries, suggesting its potential to improve wastewater treatment practices. The potential for resource recovery and energy conservation, as observed in both jar tests and full-scale operations, suggests further benefits in sustainable wastewater management. Overall, the results demonstrate the potential of Tanfloc as an effective tool for sustainable water treatment practices in diverse industrial settings.

Discussion

The analysis of Tanfloc’s performance in both jar tests and full-scale operations in the food processing industry highlights its consistent and scalable treatment efficiency, particularly in TSS removal, exceeding 90% in both the red meat industry and dairy industry. This reliability across varying conditions underscores the coagulants’ robustness and effectiveness.

Furthermore, Tanfloc’s ability to consistently address nutrient-related challenges by removing nitrogen and phosphorus in diverse testing scenarios indicates its broad applicability and adaptability. The jar tests indicate TN removal of over 40% and 70%, for the red meat and dairy industry jar tests, respectively. TP removal was found to be over 20% and 10% respectively for the red meat and dairy industries. These increased removal efficiencies across different food processing industries emphasise Tanfloc’s potential suitability for comprehensive wastewater treatment in various industrial settings.

The independently certified positive Carbon Footprint of Tanfloc reinforces its role as an environmentally responsible option for wastewater treatment. Its carbon negativity aligns with contemporary efforts in climate change mitigation, suggesting a positive environmental impact.

The increased nutrient removal rates result in a reduction in aeration requirements, observed consistently in both jar tests and full-scale operations in the food processing industry, providing strong evidence of Tanfloc’s operational benefits. These findings suggest significant cost savings in wastewater treatment processes, a critical consideration for industrial applications.

In addition, Tanfloc’s potential for recovering high-energy content materials and its impact on biogas productivity present promising opportunities for resource recovery and energy conservation. Supported by findings from both testing methodologies, this highlights Tanfloc’s role in advancing sustainable and energy-efficient wastewater treatment practices.

The consistent success of Tanfloc across diverse red meat processing facilities, observed in both testing methods, indicates its broader applicability and potential industry impact. Its adaptability positions Tanfloc as a versatile solution with implications for optimising wastewater treatment practices beyond individual facilities.

Conclusion

The evaluation of the performance of Tanfloc, a tannin-based organic coagulant, in both laboratory-scale jar tests and full-scale operations within food processing industries reveals its potential as a viable option for wastewater treatment in industrial settings.

The consistent removal efficiency of pollutants, notably surpassing 90% of total suspended solids removal under various conditions highlights Tanfloc’s reliability and scalability. This performance underscores its ability to effectively address pollutant removal challenges, laying a strong foundation for its application in diverse industrial wastewater treatment scenarios.

Tanfloc’s versatility, demonstrated by its consistent removal of nitrogen and phosphorous across different testing scales, indicates its potential applicability in addressing various wastewater compositions. This adaptability positions Tanfloc as a versatile solution for comprehensive treatment processes in various industrial settings.

The environmental impact assessment, including its carbon negativity as independently certified, aligns with the necessity for sustainable water treatment solutions. Tanfloc’s potential to contribute to climate change mitigation further underscores its environmental responsibility and potential as an eco-friendly alternative in wastewater treatment.

Additionally, the confirmed operational benefits of Tanfloc, particularly in the replicated reduction of aeration requirements validated across different testing methodologies, highlight its potential for significant cost savings.

Moreover, Tanfloc’s implications for biogas production and resource recovery, supported by findings from the testing methodologies, present opportunities for sustainable practices. It’s potential to enhance biogas productivity aligns with the increasing focus on circular economy principles and resource conservation in wastewater management.

The success of Tanfloc in diverse food processing facilities underscores its broader applicability and potential significance across industries. Tanfloc’s adaptability positions it as a versatile tool capable of revolutionising wastewater treatment practices, offering a promising shift towards sustainable water management in industrial contexts.

The results from the jar tests and full-scale operations from the red meat and dairy processing facilities indicate that Tanfloc holds promise as a transformative solution for contemporary wastewater treatment challenges. Its proven efficacy, versatility and environmental responsibility warrant further exploration and consideration for adoption in the pursuit of sustainable water treatment methodologies in diverse industrial sectors.

Acknowledgements

We would like to thank the Australian Meat Processor Corporation (AMPC) for their support in funding the research for the red meat industry cases.

The Authors

Dr. Fabiana Tessele

Dr. Fabiana Tessele, the company director, boasts over two decades of experience in water and wastewater treatment projects across various countries. She is deeply committed to water security and environmental protection, advocating for a diverse, inclusive, and well-planned approach to ensure safe water for all. Holding a Doctorate in Engineering with a specialization in resource recovery from wastewater and fluency in three languages, Fabiana has held leadership positions in contractors, environmental services companies, and multinational engineering consultancy firms. Her adeptness at rapidly building strong rapport with stakeholders is augmented by her diverse background and familiarity with multicultural environments. Fabiana’s effective communication, holistic approach, and open collaborative leadership style position her as a valuable asset in the fast-paced market. Since 2012, she has made Western Australia her home, previously serving as a Director in a multinational consultancy firm and now operating her own consultancy business. Active in the water industry, Fabiana contributes as a Peer Reviewer for the Australian Water Association and as a judge on the AWA Awards panel.

Jessica Hales

Jessica Hales, a motivated graduate chemical engineer, possesses a broad foundation in engineering principles, including process engineering, projects, and engineering design. She is passionate about innovative solutions to ensure sustainable practices and environmental stewardship, committed to working collaboratively to tackle challenges of any size. With a focus on sustainability and environmental responsibility, Jessica aims to contribute meaningfully to the field of chemical engineering, driven by her dedication to creating a positive impact on the world.

Lucas Moreno

Lucas Moreno, a Process Engineer deeply committed to sustainability, renewable energy, and leveraging technology for better solutions, brings a wealth of expertise to his role. He is genuinely passionate about developing innovative approaches to reduce greenhouse gas emissions and promote environmentally friendly practices. Focusing on sustainable solutions that enhance process efficiency, minimize environmental impacts, and ensure long-term operational efficiency, Lucas’s professional journey, spanning from Brazil to Australia, has enriched him with a diverse skill set and a broad perspective on engineering technologies and collaborative approaches. Continuously driven to explore and implement impactful solutions in the field of process engineering, Lucas is dedicated to making a difference.

References

BRATBY, J. 2006. Coagulation and Flocculation in Water and Wastewater Treatment [Online]. London, Seattle: IWA Publishing.

BREDEMANN, H. 2024. Coagulants Carbon Footprint Calculation. Tanafloc.

HALES, J. 2024. Raw Wastewater Jar Test - Dairy Industry Wastewater. Tessele Consultants.

SUOPAJäRVI, T. 2015. Functionalized Nanocelluloses in Wastewater Treatment Applications. ACTA UNIVERSITATIS OULUENSIS, 526, 22.

TANAFLOC 2024. Case Studies Across Industries. Tanafloc Australia.

UTILITIES, H. Coagulation Fundamentals.

V. DIAMANTIS, W. V., A. EFTAXIAS, B. BUNDERVOET,

V. SIEGFRIED, & AIVASIDIS, P. M. A. A. 2013. Sewage pre-concentration for maximum recovery and reuse at decentralized level. Water Science & Technology, 67.