Resilience through disasters – The reinstatement and subsequent restart of the Sydney Desalination Plant

DOWNLOAD THE PAPER

Introduction

Large scale seawater desalination was implemented across Australia by supplying all mainland state capital cities as a result of the millennium drought (1997-2009) in order to diversify and increase the resilience of municipal water supplies. In the state of New South Wales (NSW), construction began on the Sydney Desalination Plant (the Plant) in 2007 and following its completion in 2010 it operated for two years through a process proving period. By 2012 the millennium drought had broken, and the Plant entered a care and maintenance mode (termed Water Security Mode, or WSM) from June 2012. The Plant operates under rules set by the NSW Government through its Metropolitan Water Plan which outlines the primary role as a drought response asset, with provision also to provide emergency response. At around the same time, the NSW Government entered in to a 50-year lease of the Plant to a private company, Sydney Desalination Plant Pty Limited (SDP) in June 2012, that was backed by a 50-year water supply contract with Sydney Water Corporation. The Plant has since been operated by SDP.

The NSW Government approach to the resilience of water supply to the greater Sydney region has progressed in recent times, with the 2004 Metropolitan Water Plan undertaking a detailed investigation into the feasibility of not just desalination, but also groundwater and recycled water options to improve system resilience, largely in response to the Millennium Drought. This approach was further reinforced by the 2006 Metropolitan Water Plan, which detailed the progress of planning of a desalination plant in Sydney, and its importance in overall system resilience.

The Plant is located in Kurnell, NSW, and has a nameplate capacity of 250 million litres/day (MLD) and the provision for expansion of up to 500 MLD with inlet/outlet seawater tunnels, delivery pipeline and land already sized accordingly.

SDP’s key process elements include:

- Inlet and Outfall tunnels connecting the Plant to the sea off the coast of Kurnell, with a length of approx. 2.5km and diameter of 3.4m. Both tunnels have design capacity of up to 500 MLD of drinking water production.

- Intake and pre-treatment system including conventional dual media filtration.

- Over 36,000 Reverse Osmosis (RO) membranes spread across 20 process trains, utilising a partial two pass RO system.

- Dedicated energy recovery device (ERD) for each 1st pass RO system, utilizing the Dual Work Exchange Energy Recovery (DWEER) technology.

- Remineralisation of RO produced permeate, in order to meet the Australian Drinking Water Guidelines (ADWG), consisting of carbon dioxide, lime, fluorosilicic acid, aqueous ammonia and sodium hypochlorite.

- Post tensioned concrete drinking water tank with a volume of 40 MLD.

- Supply of drinking water to inner west Sydney via an 18km long, 1.8m diameter pipeline that has design capacity up to 500 MLD of drinking water production.

The Plant was still in Water Security Mode when on the 16th of December 2015, an extreme weather event (the Storm), described as a tornado, struck Kurnell with high rainfall, hailstones and unusually strong winds, measuring up to 213 kilometres per hour, which were, and remain the highest wind gusts ever recorded in NSW. The wind speeds exceeded the ultimate wind load design capacity of the Plant, resulting in significant damage to buildings and other assets, and while there were several injuries to staff working at the time, no one was badly injured.

Photo 1 – SDP immediately prior to the storm Photo 2 – SDP immediately after the storm

Following construction of the Plant in 2010, greater Sydney dam levels remained at high levels until 2018, when further drought conditions placed strain onto the system. More recent times have highlighted system vulnerabilities, namely the widespread bushfires across NSW in the summer of 2019, which were shortly followed by a significant rain event in February 2020. This combination of extreme weather events lead to an increased risk profile for greater Sydney’s water supply.

The most recent iteration of the NSW Government approach to water system security and resilience, the 2022 Greater Sydney Water Strategy, was released in August 2022. This strategy further reinforced the need for alternative and non-rainfall dependent water supplies, as well as overall system resilience. Most notably for SDP, the strategy also recommended a change in the operating rules of the Plant, that replace the original drought based operating regime, with a more flexible regime, that allows the use of SDP, not only when in drought, but also in other scenarios, such as:

- Increasing water supply by approximately 20 GL/year under average conditions, although more water supply would be available if needed due to a change in circumstances, such as an increase in water demand or a return to drought conditions.

- Extending greater Sydney water supply for up to four months during a severe drought like the 2017-2020 event, giving more time to implement drought supply measures.

- Assisting in managing water quality and other asset risks (the Plant has been operating since the drought broke in February 2020 due to water quality and treatability risks caused by bushfires and flooding).

This article aims to provide an insight into the history of SDP, describe the complex project that was the Reinstatement, and the evolution of its use as part of greater Sydney’s water infrastructure and overall system resilience.

Methods

Structure of the Reinstatement Project

Immediately following the Storm, a recovery effort was implemented to make the site safe from debris and control the risk of potential contamination from the adjacent industrial precinct. Once the site was safe, an assessment of the site assets was undertaken with insurers to determine the extent of damage. Assets were assessed and categorised under a DRUIM system (Destroyed, Repair, Undamaged, Inspect, Maintenance) to allow a scope to be developed for the reinstatement of the Plant to its pre-Storm condition (the Reinstatement Project).

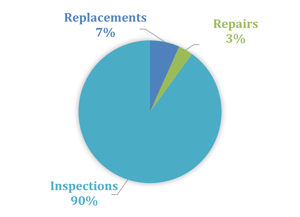

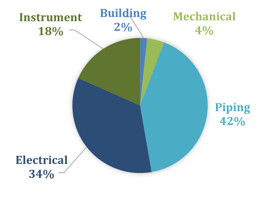

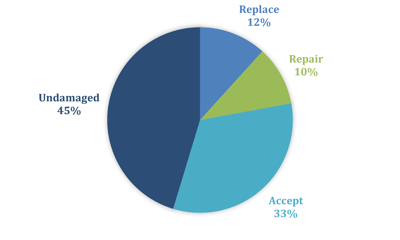

The Reinstatement Project proved to be a high risk and complex scope of works, particularly due to the catastrophic and widespread nature of damage and uncertainty of asset damage. All Plant buildings required significant repairs, and of the ~34,000 operational assets inspected, about 15% were completely replaced, with the remaining assets undergoing inspections and repairs to return them to their prior condition. Refer to figures 1 and 2 for a breakdown of the reinstatement scope.

Figure 1 – Scope Breakdown of 34,000 assets Figure 2 – Discipline Breakdown of 34,000 assets

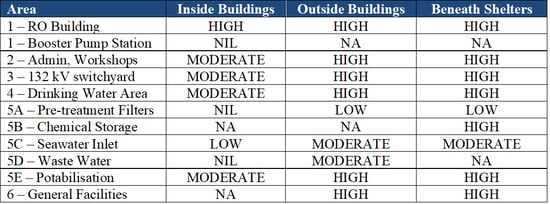

To further illustrate the impacts to the Plant, Table 1 includes a summary of the areas exposed to the Storm during the damage assessment phase in 2016.

Table 1: Classification of areas exposed to Storm damage

Coordination and alignment of objectives between operations and the Reinstatement Project teams was essential to keep the Plant in a suitable state of readiness required for Water Security Mode, maintain membrane preservation schedules, maintain assets that were not assessed as requiring replacement, and for smooth transition into the Reinstatement Project re-commissioning phase, which was led by SDP’s operator.

Rationale for the Reinstatement Testing

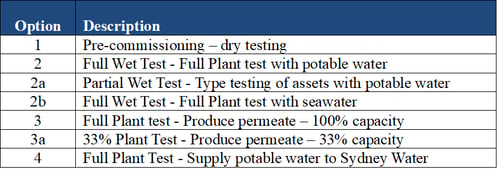

Given the complex nature of the storm damage, and the combination of both repairs and replacements across the Plant, SDP was required to develop a testing methodology that would sufficiently prove the success of the Reinstatement Project in a prudent and efficient manner. The approach taken was to consider an array of testing options, assess each for the pros and cons, and determine the most appropriate regime, with these options described in Table 2 below.

Table 2: Testing options

Of all options considered, option 2 was selected on the basis that testing included all major components of process mechanical equipment and piping systems, inclusive of both modules 1 and 2, but excluding the RO membranes, since the test fluid was potable water. For the purposes of determining whether the Plant had been restored back to pre-Storm conditions, this option was able to provide the confidence required to achieve this objective, but not to a full scale operational ready status since this scope would largely reside within a formal “restart” of the Plant under its operating rules.

Some key factors in the decision to test to the extent defined in Option 2, as opposed to a full Plant test such as Option 4 included:

- The Plant was in full scale operation for two years using seawater and producing potable water, prior to being placed into water security mode in 2012.

- The intake tunnel, outfall tunnel and delivery pipeline were all below ground and were not exposed to the Storm.

- The RO membranes were encapsulated within the RO pressure vessels, and did not sustain any significant damage.

- Two of the three 132 kV transformers were subject to repairs only, and did not require a full load test as a result of the damage they sustained during the Storm.

- The Reinstatement Project scope included the hydrostatic testing of all pipework, providing assurance that the piping systems were fit for use.

Results

Some of the significant asset interactions during the Reinstatement Project included:

- The demolition, removal and reinstatement of the two glass-lined intermediate permeate tanks (IPT) including associated building structures.

- The replacement of reverse osmosis (RO) membrane vessels whilst maintaining the integrity and preservation of existing membranes.

Intermediate Permeate Tank Replacement

SDP utilizes a partial two stage RO process, known as the 1st and 2nd pass RO. In the 1st pass RO system, the filtered seawater feed is separated into three streams:

- Front Permeate to Remineralisation System, which has passed through the membrane and has almost all of the dissolved constituents removed (< 200 µS/cm).

- Rear Permeate to RO Permeate Intermediate Tank, which has passed through the membrane and has had most of the dissolved constituents removed (< 1000 µS/cm).

- Concentrate to ERD DWEER, which contains the concentrated dissolved constituents (usually double of the seawater total dissolved solids).

The RO 2nd Pass System will receive rear permeate from the RO 1st Pass System to produce desalinated water. In normal operation each RO 2nd Pass module will receive permeate from its dedicated IPT. The tanks are hydraulically linked by an interconnection line, which enables both tanks to act as a combined volume in feeding the RO 2nd Pass module 1 and/or 2 systems.

The IPTs are made up of Permastore bolted Glass Fused ToSteel wall, floor and roof for the continuous storage of the first pass RO Permeate water, with the following characteristics:

- Effective Volume: 1,400 m

- Diameter: 13,000 mm

- Height: 12,850 mm

The system comprises Glass Fused To Steel sheets, silo bolts, roof beams and panels, stiffening and fixing members, as well as a wide range of ancillaries (manholes, flanges etc.).

The RO building was subject to the full intensity of the Storm, suffering significant damage. This included the IPTs, which were destroyed by both the direct impacts of debris (such as roof sheeting), as well as the pressures resulting from the Storm conditions, which caused a vacuum inside the tanks.

Initial stages of the works consisted of debris removal and assessment of the remaining structures for adequacy and stability. Following this, a plan was developed to safely demolish, remove, and replace the tanks with new assets.

Given the size and damage sustained to the existing tank walls, the option of dismantling the tank panels was discounted, with the safest and most efficient option being to cut the tank into pieces, for removal via a 350 t Superlift crane (see Figure 3).

Figure 3 – Destroyed IPT removal

Following the tank removal, the foundations were partially demolished (due to the embedded floor) and two new tanks of the same original specification were installed. The method of installation of the new tanks was typical of panel tank construction, with a deployed jacking system to construct the tank ring by ring until completed.

RO Membrane Vessels

SDP has over 36,000 RO membranes between its 1st and 2nd pass RO process. Encapsulating these, are 4,614 Codeline series pressure vessels. The pressure vessels are of fiberglass construction, holding 8 individual RO membranes each, designed to operate at pressures exceeding 70 bar.

Despite being within the RO building itself, the RO equipment was subject to significant damage from the Storm. The entirety of the roof sheeting, as well as other roof structural elements, was removed by the Storm damage, leading to exposure of the assets within, as well as a source of debris for impact damage to the equipment.

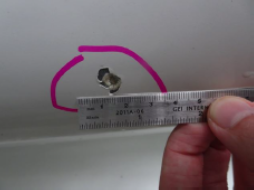

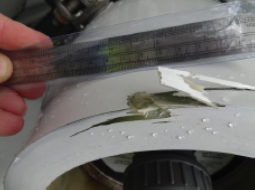

Once the area was made safe and debris removed, a detailed inspection of the RO vessels was carried out to identify the number of vessels damaged, and to categorise the damage based on agreed criteria. These criteria were based on the American Society of Mechanical Engineers (ASME) standards, as these were the relevant construction standards of the original vessels.

As the vessels are required to operate at high pressure, a significant amount of time and effort was deployed to ensure a reasonable criteria for assessing damage. In addition to the ASME standards, independent expert advice was also sought to build a robust set of criteria.

The inspections, which took place over a 2-week period, provided a detailed record of all features on the RO vessels that met the agreed criteria, determined the extent of damage sustained and classified all vessels under the DRUIM system. Examples of the typical damage are provided in Figures 4 and 5, and a summary of the DRUIM assessment in Figure 6.

Figure 4 – Chip with significant impact damage Figure 5 – Major end impact damage

Figure 6 – Outcomes of the RO vessel assessment

Figure 6 – Outcomes of the RO vessel assessment

Maintaining RO Membrane Preservation

Further to the vessel replacement, was the state of the membranes themselves, which had been subject to a preservation program since SDP entered WSM in 2012.

The long-term preservation approach included storing the RO membranes in a sodium bisulfite solution that was recirculated twice a week and changed out approximately every nine months. The RO membranes can be at risk of damage if they dry out and/ or are exposed to air for prolonged periods.

Given the criticality of the membranes to water production, and to ensure that membrane integrity was maintained during the vessel works, a detailed methodology was developed that not only detailed how the vessels would be replaced, but also how the membranes would be protected, stored, and reinstalled following vessel replacement.

Each RO train was required to have preservation fluid displaced by freshwater prior to the RO membranes being removed and drained, as well as isolation of vessel internals from oxygen exposure for no longer than a five-day duration.

The RO vessel replacement required a high level of coordination between the Reinstatement contractor, and the Plant operator. Workflows were developed to ensure clarity of responsibilities between parties, with the contractor responsible for the vessel dismantling, membrane removal, temporary storage and reinstatement. The operator maintained overall control of the RO process, including the preservation solution draining and handover of assets to the contractor, as well as recommissioning the preservation of membranes following vessel replacement.

Project Safety Performance

With the unique nature of the Reinstatement Project, the state of the site following the Storm, and the uncertainty of true asset condition, management of safety was paramount. Over the course of the Reinstatement Project, with >540,000 work hours, there were no recordable injuries. The project was also the proud recipient of the John Holland Chairman’s Award for Safety Excellence in 2017.

Numerous safety initiatives were implemented to proactively develop the positive safety culture exhibited onsite, including:

- Project safety commitment wall

- Stop work authority

- HSEQ excellence awards

- Barrier boards

- Monthly awareness campaigns

These were in addition to the daily pre-start meetings, permit to work system, tool-box meetings and daily de-brief and coordination meetings.

Outcomes of the Reinstatement Testing

Following the reinstatement of the Plant assets to their pre-Storm condition, SDP mechanically and electrically tested the Plant to confirm the successful outcome of the project and capability of restarting in response to a drought trigger within 8 months. The testing works began in mid-2018, and included the following key activities:

- Diver works to uncap the intake and outlet risers off the coast of Kurnell.

- Pre-commissioning checks of all operational equipment (approx. 34,000 assets).

- Completion of a full electrical load test to operationally load the Plant by simultaneously operating all equipment required for full plant production for up to 8 hours, where practical.

Official restart of SDP

Parallel to the efforts of SDP during the Reinstatement Project and subsequent testing works, Greater Sydney dam levels continued to decline, approaching the 60% dam level trigger several times, before recovering. As this dam level trigger is intrinsic to the operating mode of SDP, the effective planning for the restart of the Plant was challenging and uncertain. Given the recent efforts to test the Plant following the Reinstatement Project, SDP was in a good position to achieve a successful restart. However, with the dam levels hovering above the trigger limit, decision making on planning and preparing for a restart were difficult. As the Reinstatement testing works were completed, SDP was required to make a difficult decision to either maintain the Plant in a near operational state, or place it back into preservation.

Under the regulatory framework in place at the time, the costs of maintaining the Plant in a near operational state would not have been recoverable, had dam levels not fallen below 60%. With an overarching corporate objective of ensuring security of water supply to greater Sydney, SDP decided to maintain the Plant in a near operational state in case the drought worsened, and dam levels fell below the trigger level of 60%. In January 2019, the required dam level trigger of 60% was met and SDP was called upon to restart the Plant and begin full production. SDP’s decision to remain prepared for operation was integral to the success of the restart and the timely delivery of desalinated water far in advance of the expected schedule.

During the restart of the Plant, SDP also replaced all of its RO membranes (approx. 36,000) to ensure it could respond to the restart trigger and operate reliably for the period of the drought. Given global demand for desalination plants, as well as lead times for some manufacturers stretching to greater than a year, such a large membrane order was a significant risk to the successful restart of the Plant. As a result, an order was placed earlier than the official restart trigger point to ensure that membranes would be delivered and installed within the restart period. The limited operational data on membrane condition, coupled with membrane age and the criticality of SDP to protecting Sydney’s water supply supported the regulators’ recommendation that it was prudent to replace membranes upon restart. Nevertheless, the decision to order membranes prior to a restart trigger to overcome lead time challenges was a significant risk to SDP should the 60% dam trigger never have been reached.

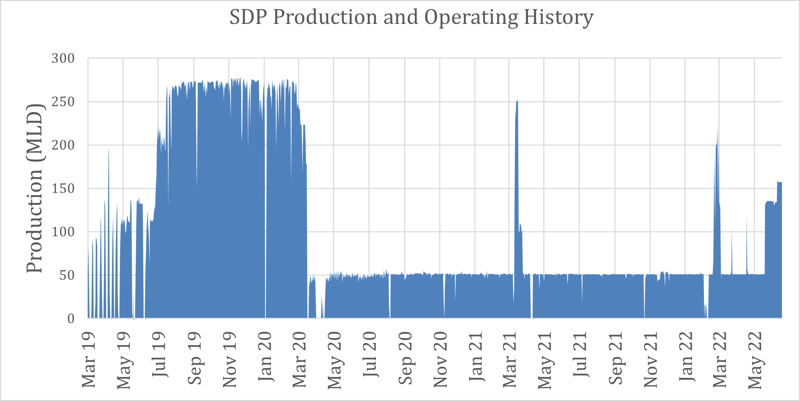

In September 2019, the 8-month restart period ended, and SDP entered its full production mode to provide water to Sydney Water during the drought period. The amount of water produced by SDP during the restart (28 GL), far exceeded requirements, in fact there was no target water production set under SDP’s operating rules during the restart period, as the focus was purely to bring the Plant back online within 8-months. The rapid response of SDP allowed significant benefits to Sydney Water’s customers by supplying additional water during the early stages of the drought when Sydney Water and the Government of NSW was keen to see the pressure taken off rainfall dependent water sources.

Between September 2019 and February 2020, SDP successfully delivered in excess of its’ nameplate capacity (250MLD) of drinking water on average, meeting customers’ needs and satisfying SDP’s role to maximise its’ water production.

Discussion

Over the summer of 2019/2020, NSW suffered widespread bushfires across the state, including the catchment for many of Greater Sydney dams. In January 2020 it was reported that over 320,000 hectares had burned in the catchment for Sydney’s main water supply, the Warragamba Dam [1]. The potential for ash inclusion and erosion runoff into the dams was a concern, should significant rainfall occur, potentially leading to water quality risks and potential algal blooms [1].

In February 2020, two significant single day rainfall events caused the Greater Sydney dam levels to rapidly rise from 42.7% to >70%, before further increasing to >90% in August that same year. This event also resulted in widespread flooding, the most severe of which were the highest since 1992 [2].

Under its operating rules, SDP began preparing for a shutdown of the Plant given dam levels had exceeded 70%, however, the extreme events of widespread bushfires followed by historic rainfall lead to the rapid rise in dam levels as well as water quality concerns from the state of the catchment and runoff. The direct impact of the significant rainfall events lead to the Warragamba Dam being isolated from supply for a brief period. Prospect Reservoir was utilised to supply Sydney, until the impactions and situation were assessed by relevant authorities [3].

Following this rain event, SDP and Sydney Water entered into an Emergency Response Agreement (ERA) in March 2020. Under this agreement, SDP operated at a continuous, reduced capacity, whilst ensuring it remained available to ramp up to full production should Sydney Water request it.

From March 2020, SDP continued to supply water to Sydney on a typical average of 50 MLD (20%) capacity, and responded to three key events, whereby it was called upon to ramp up production to assist Sydney Water in mitigating a potential public health incident in March 2021, April 2021 and again in June 2022.

The recent operating history of SDP from its restart in 2019 is depicted in figure 7 below, split into three key periods:

- The restart period, whereby the Plant production was intermittent, mainly due to resourcing constraints in the early stages, training of new staff, establishing 24/7 operations and reduced production as the assets were prepared for full operations, namely the replacement of all RO membranes.

- The full production, drought response period, noting the brief drops in production for planned maintenance shutdowns.

- The emergency response period, with stable production, planned maintenance shutdowns, as well as the ramp up in March 2021 to mitigate risks to customers following floods in NSW. At the date of writing this report, SDP remains in emergency response mode.

Figure 7 – SDP daily production since restart in 2019, showing the restart, full production (drought response) and emergency response phases of its operation.

Conclusions

Although originally designed as a drought response asset and an insurance measure for greater Sydney, the past 5 years of extreme weather events has highlighted the importance of non-rainfall dependent water supply and how these assets are utilised as part of a resilient water system.

SDP infrastructure has been subject to a complex and unique list of demands over recent history, performing to meet its obligations in these instances and highlighting the ability of the assets and expertise to be utilised to meet changing customer needs and demand.

The current direction of utilising SDP as part of a resilient water supply, rather than a pure drought response asset has required creative thinking and increased flexibility in the way that the Plant is operated. This changed the way the Plant is operated and resulted in many benefits to Sydney Water and its’ customers.

Despite a unique history, including multiple extreme weather events such as tornadoes, droughts, bushfires and floods, SDP has proven its role as an important asset to the resilient water system of NSW.

Author Biographies

Reece Karamihas, O&M Manager, Sydney Desalination Plant | A civil engineer with over ten years of experience in the water and construction industry. Reece manages operations and maintenance of the Sydney Desalination Plant and Pipeline, as well as other key business functions such as cyber security, risk and ESG.

Matt Blaikie (Co-Author), GM Operations, Sydney Desalination Plant | Matt Blaikie is a Civil and Environmental Engineer with over 15 years of experience in the water industry in the fields of operations, maintenance, treatment process engineering, project delivery and contract management and negotiation.

References

[1] Readfern, G. 2020. More mass fish deaths possible if forecast heavy rains wash bushfire ash into rivers, The Guardian, NSW, Australia.

[2] NSW Government. 2020. Flood Hawkesbury-Nepean Valley Presentation to Legislative Council Select Committee, Australia.

[3] Nyugen, K. 2020. Sydney drinking water reconnected to Warragamba Dam after contamination fears from fire and floods, ABC, NSW, Australia.