Luggage Point ANITA Mox Sidestream Treatment

Introduction

Urban Utilities with our partner Veolia have delivered the first Australian installation of the ANITA™Mox (anammox) sidestream treatment process at the Luggage Point Resource Recovery Centre (RRC). The complex path from research to delivery has been supported in partnership with the University of Queensland (UQ). The anammox plant was seeded in January 2020 with pre-colonised anammox carriers from an onsite bio-farm facility. The anammox system is now successfully treating up to 900 kgN-NH4/day, which is significantly in excess of the 800 kgN-NH4/day design capacity from the sidestream return, with removal efficiency exceeding 90%. The major focus of this paper is to describe the success of the technology for Urban Utilities customers, providing significant operation savings in excess of $500K pa, through the removal of ethanol dosing onsite, whilst maintaining excellent effluent quality. Excitingly Urban Utilities anammox seed is now functional in Australia, available in an operating bio-farm. This seed can be easily accessed to seed other process. In this paper some international case studies are reviewed, which highlight the adaption of seed products for other end user applications in the USA and Europe. The technology is proving flexible around the world even to treat challenging centrate feeds.

Year Case Study was Implemented

2020 to 2022

Case Study Summary

This paper will focus on the implementation of Australia’s first full-scale municipal anammox system, benchmarked against overseas installations and the benefits delivered. Furthermore, how the anammox installation at Luggage Point RRC supports Urban Utilities focus on embracing circular economic practices.

Operational results for other ANITA™ Mox plants in Europe and US will be compared to the plant delivered at Luggage Point. This includes comparing the technologies flexibility when operated in a variety of design configurations and treated centrate from a range of conventional or advanced anaerobic digester (AD) processes including thermal hydrolysis process (THP).

Case Study Detail

The specific issue

As populations grow, it’s important Australian Wastewater Treatment Plants (WWTPs) identify cost-effective methods to manage effluent total nitrogen (TN) levels and meet their environmental obligations. It is also expected that a large amount of organics will be re-directed to wastewater treatment facility driven by the National Waste Policy Action Plans to halve organic waste to land by 2030. These incoming changes will drive demand for (i) extra infrastructure (tank volume, equipment), (ii) chemicals such as external carbon source addition to increase denitrification capacity, and (iii) energy due to higher aeration capacity for nitrification.

Biological nitrogen removal via nitrification/denitrification has been the predominant approach to the treatment of municipal and domestic wastewater in Australia since the establishment of the Australian National Water Quality Management Strategy guidelines. Although effective for the nitrogen removal, this process is energy intensive due to aeration requirements and may require carbon supplementation depending on the wastewater composition and/or plant design to meet low total nitrogen (TN) level in the final effluent.

In recent years anammox has been viewed as an emerging alternative to conventional nitrogen removal technologies due to its efficient biological ability to short-cut the nitrogen cycle, without the need for an additional carbon source (Lackner et al, 2014). By taking advantage of this efficient biological process, wastewater service providers can benefit from the implementation of anammox, improving ammonium removal efficiencies, future proofing plants against increased digester utilisation and reducing operational costs.

Approach Developed

The business case for anammox was driven by an opportunity for Urban Utilities to reduce the OPEX spent on ethanol dosing for nitrogen removal. However, the looming drive to create flexibility to manage the increased nitrogen load associate with the importation of organics was acknowledged and at the time viewed to provide increased flexibility at Luggage Point. In line with Urban Utilities strategic pathway to embracing circular economic practices, the organisation has now commenced the importation of organics for co-digestion, which now represents a 10% increase in digester utilisation. This will benefit the community by reducing the cost to treat wastewater, through commercial utilisation of its assets, ultimately increasing gas and energy production and creating environmental benefits by preventing organic material ending up in landfill. Whilst the redirection of organics to digesters provides significant benefit towards offsetting the plants total energy requirements through methane generated power, the return flows from the digesters “sidestream” TN loads contribute significantly to the plant’s operational costs. Urban Utilities installation of the anammox system ensures this strategy is sustainable, reducing the TN load to the mainstream process by treating the side-stream separately. By taking advantage of this Australian first technology, Urban Utilities has taken a step towards long-term sustainable wastewater treatment services for customers by reducing operating costs and unlocking process capacity of treatment plants, together benefiting the triple bottom line.

Summary of activities and their implementation

The anammox journey in Australia began in 2011 in partnership with the University of Queensland creating the initial seed stock. This was one of the first projects started at the dedicated research facility, the Luggage Point Innovation Centre, which now hosts a number of local, national and international projects to the value of 20 million dollars. Unable to import the bacteria into Australia due to biosecurity restrictions, Urban Utilities Veolia and UQ started growing up the anammox biomass using an initial 10 L jar of laboratory grown anammox. This inoculum was used to carefully grow-up the seed stock in a couple of 200L drums to provide enough biomass to perform a 4m3 pilot trial in 2014 using sidestream wastewater (Hu et al., 2015). After several years of piloting, Urban Utilities decided to move to a full-scale sidestream anammox process for the Luggage Point RRC. To proceed with this implementation at full-scale, a larger amount of seed media was needed than available in the 6m3 pilot plant. To grow this seed media, Urban Utilities installed an 8m3 biofarm at their innovation centre in 2017, followed by a larger 50 m3 biofarm tank in 2019 (Figure 1). The full-scale installation was seeded in January 2021 with a total 22m3 carriers from the biofarm.

Figure 1: Scale-up journey to grow anammox bacteria locally for 1st ANITATM Mox in Australia

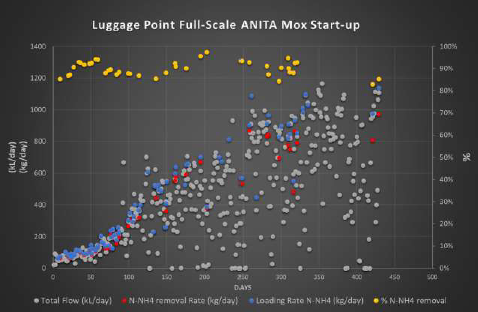

In parallel to growing the seed biomass, Urban Utilities, Veolia and Fulton Hogan embarked on the process of designing and building the new full-scale sidestream anammox process. The project objective included providing a low-cost upgrade solution at the Luggage Point RRC to accommodate the new full-scale sidestream anammox process. This was achieved by repurposing four unused pre-treatment tanks, which required an innovative design to overcome the hydraulic limitation, shape and configuration of the tanks, without the aid of mechanical mixing. The final solution required altering the four tanks to operate in series, consisting of two hydraulicity connected compartments. This configuration also had the added benefit of improving the seeding process, which only required the seeded media to be added to the front pair of tanks. This configuration had proven to be successful in the rapid seeding of media at the innovation centre prior to the design of the full-scale plant. The initial expected timeframe from seeding to design loading rate was estimated to take 3-6 months based on previous experience, however due a hydraulic limitation within process, the plants flow was restricted 4 months after seeding just as it had entered the exponential growth phase (Figure 2). This was rectified 250 days post seeding (Sep 2021), enabling the anammox facility to reach its design treatment capacity within weeks.

Figure 2: Anammox Performance from start-up to design loading rate.

The full-scale facility is now successfully treating over 1,000m3/day of high strength centrate return from the anaerobic digestion process with removal efficiencies exceeding 90%. At the current centrate concentration of 900-1,100 mgN-NH4/L this equates to a loading rate over 1,000 kgN-NH4/day. The current performance of the Luggage Point ANITA™ Mox from start-up has already proven to be consistent with the other 25 ANITA™ Mox plants in operation elsewhere in the world market. Whilst this is a first for Australia, the performance of the new ANITA™ Mox installation illustrates the flexibility of the technology for retrofitting and should provide confidence for the Australian industry even with challenging feed waters including THP. The ANITA™ Mox carrier is now ready as a seeding product for other Utilities in Australia. This is a significant milestone for the Australian industry and enables a more rapid commissioning process of other plants. It is important to also take a global view to understand the success of international uptake of the process. The following case studies presented demonstrate the flexibility and reliability of the anammox process in several international sidestream configurations.

| Name | Flow WWTP (MLD) | Type of centrate | NH4 load (kgN/d) | Design flow (m3/d) | NH4 level (mgN/L) | ANITA Mox config. | Start-up Year |

| Denver (US) | 850 | AD | 4,000 | 3,400 | 1,200 | MBBR | 2017 |

| Luggage Point (AU) | 130 | AD | 975 | 1,000 | 975 | MBBR | 2021 |

| Toulouse (FR) | 160 | THP + AD | 1,800 | 1,000 | 1,800 | IFAS | 2020 |

Denver, CO: Largest Anita Mox to Date

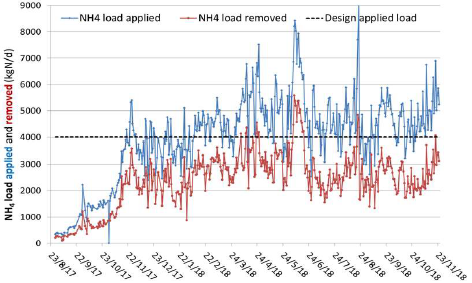

The Metropolitan Water Reclamation District (MWRD) in Denver, CO USA, installed the largest ANITA™ Mox plant to date at its Robert W. Hite Water Reclamation Facility (850 MLD) by converting an existing return activated sludge (RAS) reaeration basin into two parallel ANITA™ Mox Moving Bed Bioreactor (MBBR) (Figure 3). The centrate design flow is 3,400 m3/d with a NH4 load of 4,000 kgN/d at a concentration of 1,200 mg-N/L. The process started in August 2017 with 5% of seed media coming from US and Europe ANITA Mox plants. As seen in (Figure 4), it took only 13 weeks to reach the full design load, while starting with only 5% of seed media (Lemaire and Christensson, 2021).

Figure 3: Photo of the ANITA Mox reactor in Denver retrofitted into an existing RAS reaeration tank. Red box indicates the location and footprint of the installation (Adapt from Lemaire and Christensson, 2021).

Experiences during this start-up include instances of loading over design, variable flow, high polymer residual, and high TSS spikes. The ANITA™ Mox was very resilient to all of these disturbances thanks to the robustness of the MBBR system and its complete anammox biofilm retention feature. The goal of MWRD is to load the ANITA™ Mox to its maximum capacity (consistently above design load by 20–50%) targeting a residual NH4 level between 200 and 300 mg-N/L. It results in a lower NH4 removal efficiency (65–75% instead of >85%) but allows them not to dose any extra alkalinity despite being limited in their centrate (Lemaire and Christensson, 2021).

Figure 4: NH4 load applied and removed (in kgN/d) at Denver since start-up of the ANITA Mox (Lemaire and Christensson, 2021).

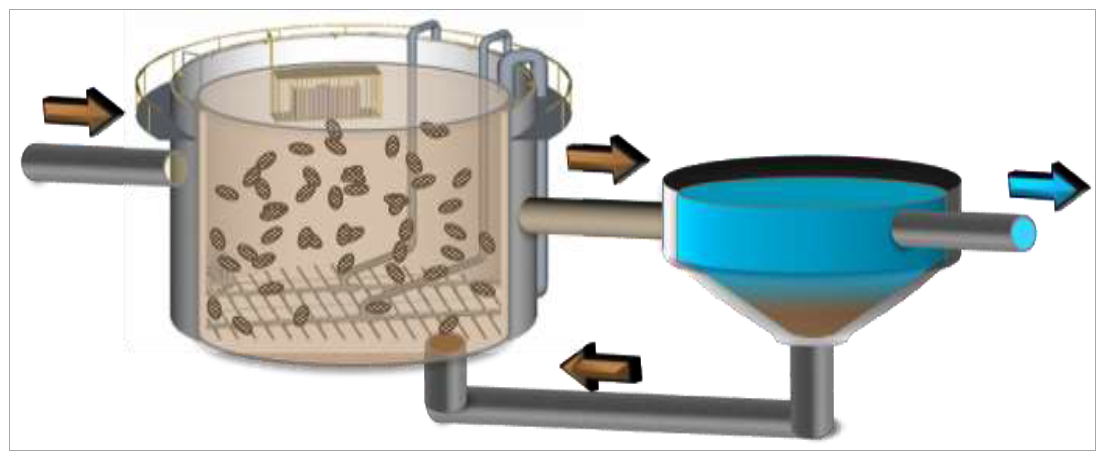

Lessons Learned from Treating THP Centrate

When THP is introduced into the sludge treatment process, not only does ammonium and soluble Chemical Oxygen Demand (COD) concentration increase, but also intermediate inhibitory compounds that typically require dilution of the centrate to maintain high removal performance. For this application, the integrated fixed-film activated sludge (IFAS) configuration of ANITA™ Mox (Figure 4) has proven to be more robust than the MBBR configuration due to the buffering capacity of the heterotrophs and the increased amount of ammonium oxidising bacteria (AOB) in the mixed liquor suspended solids (MLSS), whereas the anammox bacteria are safely retained on the media (Lemaire et al. 2015; Hollowed et al. 2019). Today, there are eight ANITA™ Mox units treating THP centrate: Växjö (Sweden), Grindsted (Denmark), FiveFords (UK), Toulouse (France), Osberstown (Ireland) that are in operation and Ljubjlana (Slovenia), Piscataway (US), Raleigh (US) that are under design or construction (Lemaire and Christensson, 2021).

Figure 5: IFAS ANITA Mox configuration (Lemaire and Christensson, 2021).

Toulouse (France): Largest IFAS ANITATM Mox

Toulouse Metropole decided to upgrade the sludge treatment line at the Ginestous WWTP (1M PE). The new sludge line is composed of BioThelysTM THP, two large anaerobic digesters of 6,000m3 each, and a MemGasTM biomethane purification unit to produce 56 GWh/year that will be reinjected into the city natural gas grid. For the cost-effective removal of the NH4 load returned to the WWTP, an IFAS ANITA™ Mox is treating all the centrate generated by the THP and AD. Figure 5 shows a 3D illustration of the new sludge treatment line with the IFAS ANITA™ Mox highlighted in red. The new sludge line is still under the final commissioning stage but is already treating all the sludge produced by the plant today, approximately 45 total dry solids (tDS)/day for a design load of 73 tDS/d in 2035. The IFAS ANITA™ Mox is designed to treat a NH4 load of 1,800 kgN/d with a centrate flow of 1,000 m3/d in 2035. Today, it is already treating all the centrate produced by the THP + digester (approximately 900 m3/d corresponding to 800–1000 kgN/d) despite having been seeded with only 8% of pre-colonised anammox media (Lemaire and Christensson, 2021).

Figure 6: Three-dimensional (3D) drawing of the THP + AD sludge treatment extension project in Toulouse and photo of the IFAS ANITA Mox unit (Adapt from Lemaire and Christensson, 2021).

Summary of outcomes and measurable impacts

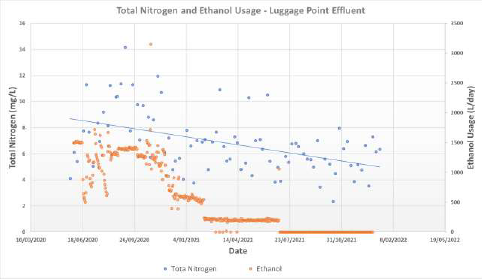

The Luggage Point RRC is located at the end of Brisbane River and discharge its effluent to Moreton Bay. The bay is an environmentally significant area that supports a vast array of marine life in South East Queensland (SEQ). Managing nutrient emissions from the Luggage Point STP, specifically nitrogen and phosphorous, therefore plays an important role in maintaining the health of the bay. The delivery of this project is a great example of finding a solution that offers the perfect balance of a positive environmental and socially appreciated solution to a problem while reducing costs. The environmental benefits to date have been significant with the continued reduction in effluent TN, 60 tonnes below the previous year without the aid of ethanol dosing for denitrification (Figure 7).

The Luggage Point centrate ANITA™ Mox process benchmarks well against operating parameters and costs savings observed across the 25 other international installations. The economic benefits of the project have now resulted in the complete removal of ethanol dosing from Luggage Point with an annual saving of over $500,000 per year. This has also coincided with improved treatment capacity with the bioreactors which has aided the reduction in TN discharges to historic low levels. The additional treatment capacity has also supported the business opportunity for external importation of nitrogen-rich organic wastes for increased gas and energy production to further offset plant energy requirements. Urban Utilities commenced the importation of fats oils and grease (FOG) waste to its digesters in 2021, representing a 10% increase in digester Utilisation.

Figure 7: Total Effluent Nitrogen and Ethanol usage at Luggage Point RRC

Important lessons learnt and critical success factors

Prioritising the anammox project delivery, which offered operational efficiency over other major infrastructure projects was challenging. In a key sign of leadership, Urban Utilities made the decision in 2019 to include anammox project as one of the organisations top 10 priority for delivery. This empowered a cross business collective commitment to dedicate appropriate resources and a commitment to the value of this innovative projects and enabled a timely delivery.

The strategic decision to lead the development of the anammox seed stock through to its implementation was pivotal to success and rapid deployment of Australia’s first anammox system. Bringing this process inhouse, instead of procuring an off-the-shelf solution, enabled Urban Utilities to develop a significant level of knowledge and expertise. This was used to help develop a system with increased flexibility and the robustness to improve performance and reduce process upsets. This skillset is now present in Australia and is available for capability build of other end users of the ANITA™ Mox across Australia. The ANITA™ Mox Plant at Luggage Point will be run as a biofarm – providing seed for other ANITA™ Mox plants across Australia, enabling industry to fast track new projects by deleting the costly and lengthy process of growing the seed themselves.

The Luggage Point ANITA™ Mox project and the case studies presented in this paper demonstrate the viability and success of anammox for sidestream treatment from both AD and THP+AD. This provides the industry confidence in the technology especially for those considering the use of the anammox technology as part of their wastewater treatment upgrades.

References

Lackner, S., Gilbert, E., Vlaeminck, S., Joss, A., Horn, H., & Van Loosdrecht, M. (2014). Full-scale partial nitritation/anammox experiences. Karlsruhe: Elsevier.

Hu S., Lemaire R., Rattier M., Lockie H., Harding E., McPhee P. & Keller J. (2015) Pilot-scale Demonstration of ANITA MOX Process for Sidestream Deammonification. Proceedings OzWater Conference, Adelaide, May 2015.

Lemaire R. & Christensson M. (2021) Lessons Learned from 10 Years of ANITA Mox for Sidestream Treatment. Processes 2021, 9(5), 863.

Lai K., Hollowed M., Qin C., Storino L., Wawczak B., Brand M., Thesing G. (2017). Start-up of Sidestream Deammonification at MWRDGC’s John E. Egan Water Reclamation Plant. Proceedings WEFTEC 2017, Chicago, Oct 2017.

Lemaire R., Veuillet F., Bausseron A., Chastrusse S. Monnier R., Christensson M., Zhao H. Thomson C., Ochoa J. (2015). ANITA Mox deammonification process for COD-rich and THP reject water. Proceedings WEFTEC 2015, Chicago, Oct 2015.