Identifying alternative treatment options for removal of bushfire-related contaminants

First published in Water e-Journal Vol 8 No 1 2022.

Sydney Water’s extensive treatability tests on Warragamba Dam successfully identified a two-stage pre-treatment process to remove contaminants and supply safe drinking water to the 4 million people it services.

DOWNLOAD THE PAPER

Abstract

Sydney’s Warragamba catchment was severely burnt by bushfires during a period of extreme drought in 2019. Sydney Water carried out extensive water quality analysis and treatability tests using bushfire ash from the catchment to determine the impact of bushfire ash on both raw water and drinking water quality and treatability. Water quality analysis showed a significant increase in turbidity, colour, organics, metals and nutrients in the ash-laden water. Extensive treatability tests successfully identified alternative treatment options for effective removal of these bushfire-related contaminants. Following the bushfire, drought-breaking heavy rainfall rapidly filled up Warragamba Dam and deteriorated the raw water quality as indicated by ash-laden water tests. Sydney Water’s extensive tests on water contaminated with bushfire ash provided early information on water quality and treatability impacts which helped to prepare risk management approaches for the drought-breaking rain event. Sydney Water continued to manage and treat poor-quality source water (and supply safe drinking water to the customers) by comprehensive testing and optimisation at relevant Water Filtration Plants.

Introduction

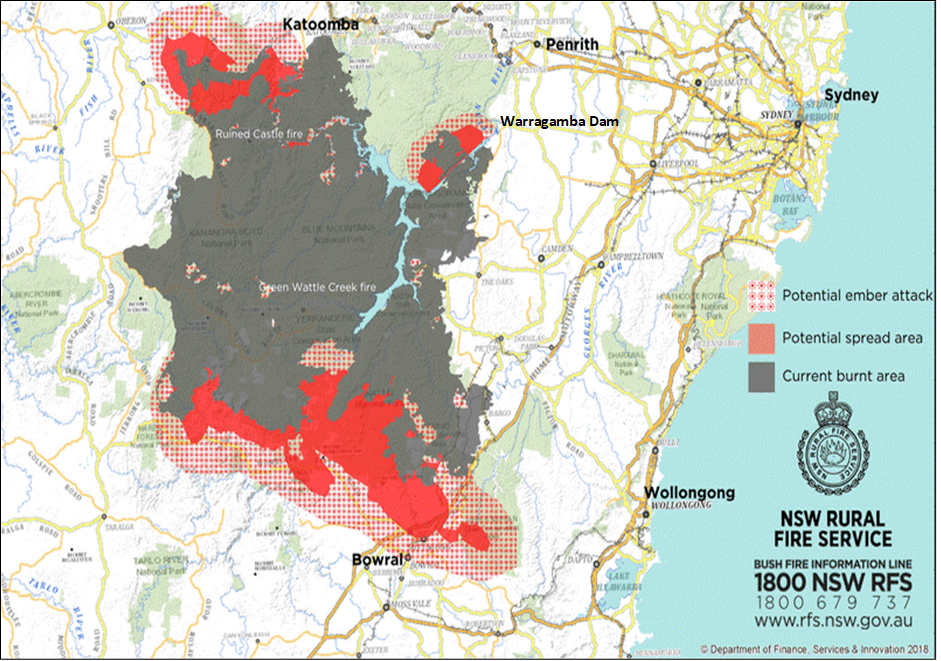

Sydney’s Warragamba catchment was in extreme drought in 2019 and Warragamba Dam, which supplies 80% of water to Greater Sydney, was depleted to about 40% storage level. Warragamba Dam supplies raw water to three water filtration plants (WFPs) which service a population of around 4 million people in Greater Sydney. During the period of extreme drought, in December 2019 and January 2020, a significant bushfire severely burnt the catchment (Figure 1).

Sydney Water carried out extensive tests using bushfire ash from the Warragamba catchment and determined the impact of the ash on water quality and treatability. Following the bushfire, drought-breaking heavy rainfall occurred in the catchment in February 2020, which filled up the Warragamba Dam from around 40% to over 80% within a few days. Bushfire ash and flood debris were washed into the dam and had a major impact on the raw water quality.

Highlights

- • Bushfire ash increases turbidity (>100 NTU), true colour (>50 HU at 400nm), organic matter (DOC >10 mg/L), metals and nutrients in water.

• Turbidities and suspended solids can be effectively removed by a natural and/or chemical-assisted settling process.

• Organic matter and colour of ash laden water is difficult to remove through direct filtration.

• Nutrients have the potential to increase algae numbers.

• Treatment of ash laden water can be successfully done using chemical assisted sedimentation, two stages of coagulation, low pH coagulation, powdered activated carbon (PAC) dosing and potassium permanganate dosing.

Figure 1. Extensive Bushfire in the Warragamba Dam Catchment Nov 2019 - Feb 2020 (NSW Rural Fire Service 2020)

Methodology

Two types of bushfire ash were collected from Warragamba catchment – mild-intensity burnt ash and high-intensity burnt ash. Batches of ash-laden water were prepared by blending bushfire ash with Warragamba Dam raw water and standardising the batches for three different true colours - 10 Hazen Units (HU), 20 HU and 50 HU at 400nm. Batches of ash laden water contained 1%, 2% and 4% by volume of mild-intensity burnt ash for true colour of around 10 HU, 20 HU and 50 HU, respectively, and 12% and 24% by volume of high-intensity burnt ash for true colour of around 10 HU and 20 HU, respectively. Following the drought-breaking heavy rainfall, intrusion water from the Warragamba Dam was also collected and tested to compare with the ash laden water tests. Water qualities of ash laden water and intrusion water were analysed for turbidity, true colour, total suspended solids (TSS), dissolved organic carbon (DOC), total organic carbon (TOC), ultraviolet (UV254) absorption, aluminium, iron, manganese, phosphorous, ammonia, nitrite and nitrate. The treatability of ash laden water and intrusion water from the dam was tested in a series of Jar tests in various combinations of treatment set-up.

Results and Discussion

Ash laden water quality

Visual assessment revealed that mild-intensity burnt ash was comparatively brown in colour, whereas high-intensity burnt ash was black (Figure 2) after blending with Warragamba Dam raw water. Mild-intensity burnt ash produced colour and organic matter at a faster rate in the produced raw water than high-intensity burnt ash.

Figure 2: Mild-intensity burnt ash (right) and High-intensity burnt ash (left)

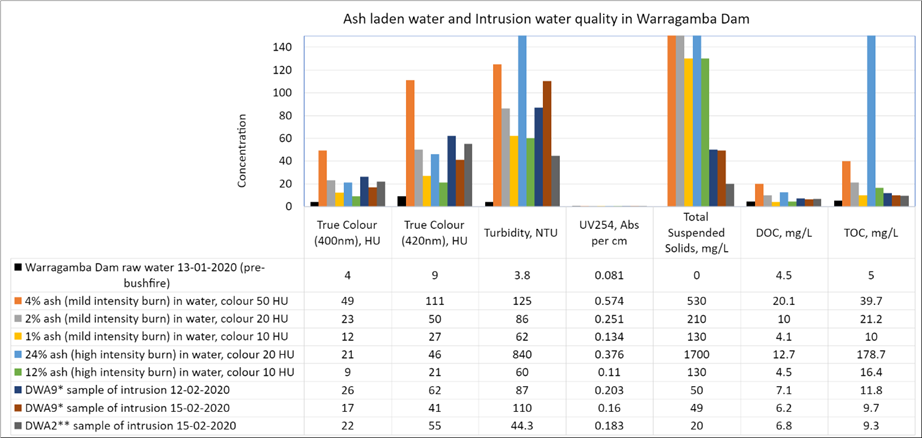

Ash laden water contained significantly higher concentrations of turbidity, TSS, true colour and organics (DOC, TOC, UV254 absorption), compared to baseline water qualities of Warragamba Dam pre-bushfire (Figure 3). For a 4 % mild-intensity burnt ash in water, test results showed that, compared to pre-bushfire water, turbidity increased by 33 times, true colour 12 times, UV254 absorption 7 times, DOC 4.5 times and TOC 8 times.

Analysis of water quality data showed that a much lower concentration (2%) of mild-intensity burnt ash produced a similar true colour (e.g., 20 HU at 400 nm) in water as produced by a much higher concentration (24%) of high-intensity burnt ash. This result indicates that, for the same concentration of ash in water, mild-intensity burnt ash produces higher true colour and dissolved organic carbon (DOC) than high-intensity burnt ash.

For a similar true colour (e.g., 20 HU at 400nm) in water, high-intensity burnt ash produced significantly higher turbidity (10 times), TSS (8 times) and TOC (8.4 times), compared to mild-intensity burnt ash. This result shows that, high-intensity burnt ash contributes to elevated turbidity, TSS and TOC in water.

Analysis showed that, initial (12-02-20) intrusion water quality at the sample point DWA 9, which is 14 km upstream of the dam wall, was similar to 2% mild-intensity burnt ash laden water for turbidity and true colour, but slightly lower DOC, TOC, UV254 absorption and TSS, which is possibly due to significant blending in the large water body.

* DWA9 is the sample point in Warragamba Dam which is located 14 km upstream of dam wall

** DWA2 is the sample point in Warragamba Dam which is located 500 m upstream of dam wall

Figure 3: Ash laden water and intrusion water analysis for turbidity, true colour, suspended solids and organics

As presented in Figure 4, ash laden water contained higher concentrations of total metals (aluminium, iron and manganese). However, concentrations of filtered (soluble) metals were comparatively low. For a 4% mild-intensity burnt ash in water, results showed that (Figure 4), compared to pre-bushfire water, total aluminium increased to 75 times, iron 47 times and manganese 10 times. Intrusion water in the Dam also contained an elevated concentration of metals in water.

* DWA9 is the sample point in Warragamba Dam which is located 14 km upstream of dam wall

** DWA2 is the sample point in Warragamba Dam which is located 500 m upstream of dam wall

Figure 4: Ash laden water and intrusion water analysis for metals concentration

Ash laden water contained a significantly higher concentration of phosphorous (Figure 5), compared to pre-bushfire Warragamba water, which has the potential to cause algae growth in warmer conditions. The ammonia concentration was also higher in ash-laden water. Intrusion water contains higher concentrations of nitrite.

* DWA9 is the sample point in Warragamba Dam which is located 14 km upstream of dam wall

** DWA2 is the sample point in Warragamba Dam which is located 500 m upstream of dam wall

Figure 5: Ash laden water and intrusion water analysis for nutrients

Treatability and drinking water quality

An extensive Jar tests program was designed and carried out with various combinations of pre-chlorination, coagulation by ferric chloride and polyDADMAC doses, followed by filtration mimicking the direct filtration process at Sydney Water.

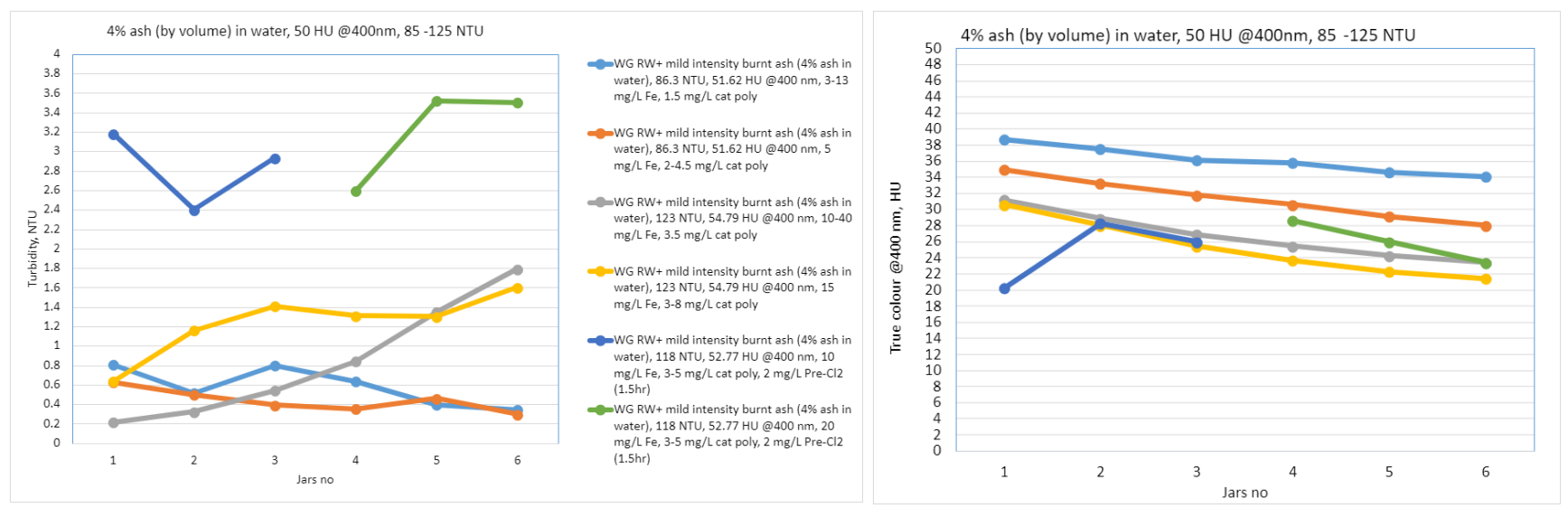

Jar test results showed (Figure 6) that water was coagulable and ash laden water turbidity of over 100 NTU could be removed by an optimised coagulant dose, which could achieve a filtered water turbidity <0.50 NTU. However, a significant amount of solids settled in the Jars, which would rapidly increase filter head-loss, reduce filter run time and production capacity in a direct filtration process. True colour in ash laden water of around 50 HU at 400 nm could not be sufficiently removed in Jar tests, meaning that drinking water would have higher true colour and organics following treatment by coagulation and direct filtration. Therefore, it has the potential to increase the formation of disinfection by products (DBPs) such as trihalomethanes (THM) formation following chlorine disinfection of the treated water.

Figure 6: Example of Jar test results for ash-laden water with high turbidity and colour, and at various combination of pre-chlorination, coagulation and direct filtration

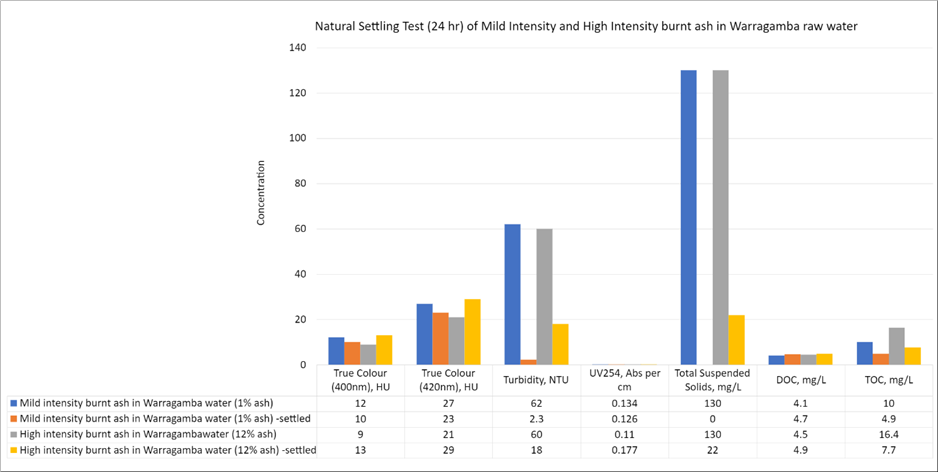

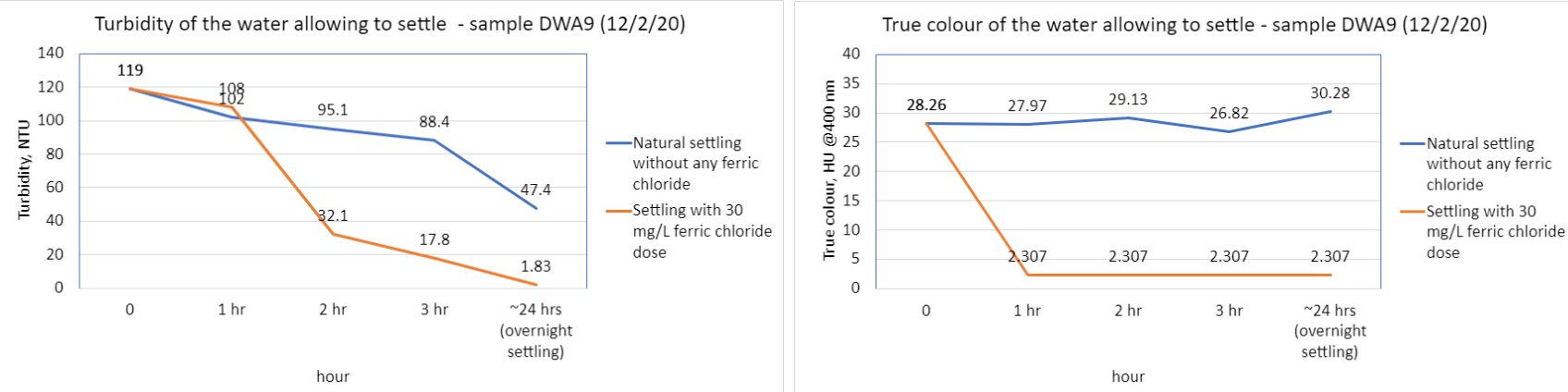

Jar tests were carried out to naturally settle ash laden water. Natural settling tests for 24 hours reduced the turbidity values by 50-90%, and the TSS values by 80-95% for ash laden water (Figure 7 and Figure 8), but true colour and DOC were not reduced by natural settling (Figure 7). These results demonstrate that, with reasonable settling in the dam, concentrations of particulate matter in the water column (e.g., turbidity, TSS) will improve, but dissolved matter (e.g., true colour, DOC) will not settle, and will remain at an elevated concentration in the dam.

Several Jar tests were carried out by dosing coagulant into the ash-laden water and then allowing settling in the jars. Chemical assisted settling using a 30 mg/L ferric chloride dose significantly reduced the true colour of the ash-laden water from around 30 HU to <3 HU at 400 nm, and turbidity was also removed at a faster rate, compared to natural settling (Figure 8). Therefore, as a first step, pre-treatment of ash laden water with coagulant dosing, followed by a settling process in a clarifier or sedimentation tank, will significantly remove suspended (e.g., turbidity, TSS) and dissolved contaminants (e.g., colour, organics).

Figure 7: Water quality analysis before and after 24-hour settling test

Figure 8: Settling tests for natural settling and chemical assisted settling by ferric chloride dose – raw water sample DWA 9 (the sampling point is 14km upstream of the dam wall)

Jar tests were carried out using intrusion water in the dam with a turbidity of 110 NTU and a true colour of 17 HU at 400 nm. Results (Figure 9) showed that a notable improvement in filtered water quality (e.g., Turbidity, TSS, True colour, UV254, DOC and TOC) was achieved when second stage coagulation and filtration were performed following first stage chemical-assisted settling using a 10 mg/L ferric chloride dose. Tests also showed that much higher removals of DOC, TOC, UV254 and true colour were achieved in filtered water by applying chemical assisted settling in the first stage, compared to natural settling in the first stage. From an initial DOC of 6.2 mg/L, DOC was reduced by 24% in coagulation and direct filtration (to 4.7 mg/L), 17.7% in natural settling for 24 hrs (to 5.1 mg/L), 38.7% in natural settling followed by coagulation & filtration (to 3.8 mg/L), 27.4% in chemical-assisted settling by 10 mg/L ferric chloride dose (to 4.5 mg/L), and 51.6% in chemical assisted settling followed by a second stage coagulation and filtration process. Therefore, two-stage coagulation is an effective water treatment process for ash laden water, with a first stage chemical dosing (coagulation) and sedimentation process, and then a second stage of coagulant dosing into the settled water from the first stage, followed by filtration.

Figure 9: Intrusion water tests for coagulation and filtration, with and without chemical-assisted settling

Potassium permanganate dosing was very effective in oxidising and removing raw water manganese of around 400 µg/L of dam water and this maintained a drinking water manganese level of <10 µg/L.

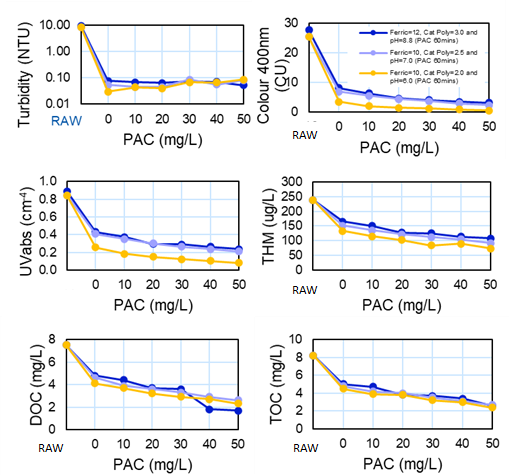

Following settling, ash laden water was tested by incremental doses of powdered activated carbon (PAC) in the water. PAC dosing, followed by coagulation and direct filtration, significantly improved filtered water colour and organics (DOC, TOC, UV254 absorption) (Figure 10). A dose of 50 mg/L PAC reduced DOC from 7.4 mg/L to 3.0 mg/L, and TOC from 11.2 mg/L to 3.3 mg/L (Figure 10). Therefore, if the raw water contains lower turbidity (following settling in the dam), which is within the design limit of the direct filtration plant, then PAC dosing will be a very effective process to apply in the direct filtration to remove both organics (DOC, TOC, UV254) and true colour of ash-laden water.

Figure 10: Impact of powered activated carbon (PAC) dose on filtered water quality

Intrusion water from the Warragamba Dam was also tested using incremental doses of PAC in jar tests and using coagulant doses in direct filtration. As presented in Figures 11 and 12, the results showed that significant improvements in treated water DOC, TOC, True colour, UV254 absorption and THMs were achieved with incremental dose of PAC (Figure 11). Tests were also carried out at three different coagulation pH values, which demonstrated that a lower coagulation pH is more effective for removing colour, UV254 absorption, DOC, TOC and THMs when combined with a lower polyDADMAC dose. A dose of 50 mg/L PAC at a coagulation pH 6.0 removed DOC from 7.5 mg/L to 2.3 mg/L, TOC from 8.2 mg/L to 2.4 mg/L and THM formation potential (72 hours tests) from 239 µg/L to 74 µg/L. However, a lower coagulation pH would hinder the metal removal by oxidation process, so it is not suitable for a direct filtration process when the raw water contains elevated metals.

Figure 11: Impact of powdered activated carbon (PAC) dose and pH on filtered water quality – sampling point is at 80 m depth of the dam at DWA2 (500m upstream of the dam wall)

Therefore, it is recommended that a two-stage coagulation flocculation process would be most effective for ash-laden water treatment where a low pH coagulation (pH~6.0) with PAC dosing and a settling process can be applied as the first stage to significantly remove true colour, DOC, TOC, UV254 absorption and THMs, and in the second stage using a high pH coagulation (pH >8.5) potassium permanganate dosing followed by filtration can be applied to remove metals.

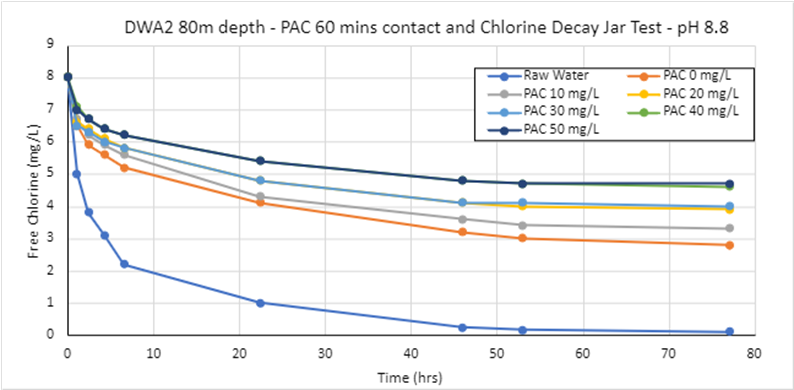

PAC treated filtered water was also tested for chlorine decay for a period of 4 days to determine the impact of chlorine decay on the drinking water distribution network. Results (Figure 12) showed that a notable improvement in chlorine decay was achieved by an incremental dose of PAC, which can be correlated to increased levels of organics removal by PAC dose.

Figure 12: Impact of powdered activated carbon (PAC) dose on chlorine decay of filtered water – sampling point is DWA2 (500m upstream of the dam wall) at 80 m depth in the dam

Conclusion

Sydney Water’s extensive tests on water contaminated with bushfire ash provided early information on water quality and treatability impacts, and helped to prepare risk management approaches for the drought breaking rain event. Test outcomes informed treatment plant optimisation to manage poor-quality events of source water from Warragamba Dam and secured a safe drinking water supply that fully complied with the Australian Drinking Water Guidelines. Water quality analysis and treatability tests using water contaminated with bushfire ash filled a knowledge gap about bushfire impacted source water treatment.

Acknowledgement

Authors would like to thank WaterNSW for providing burnt ashes from the catchment and intrusion water samples from the dam for this study. We also wish to thank Jack Budgen for his help with the jar tests and chlorine decay tests.

References

NSW Rural Fire Service, 2020. Bushfires Map, www.rfs.nsw.gov.au.

Author Biographies

ASM Mohiuddin | ASM Mohiuddin currently works as Process Manager in Customer Delivery -Water Supply & Production at Sydney Water. He has over 19 years of process engineering experience in the industry and currently leads a process engineering team at Sydney Water. Mohiuddin works on drinking water improvement projects, manages research and development trials in pilot and prototype scale, optimises water filtration plants, reviews process design and selection of treatment technologies in water treatment upgrades at Sydney Water. Mohiuddin has a Bachelor of Science degree in Chemical Engineering and a Master of Engineering degree in Water & Wastewater.

Yue-Cong Wang | Yue-Cong Wang is a Senior Process Engineer and Modelling Specialist at Sydney Water. He has over twenty-eight years of numerical modelling and model development experience gained through practical and research activities in the water and wastewater fields. He also has very strong computer programming skills and has developed a lot of customised software for data manipulation, management and presentation in support of hydraulic and environmental modelling activities, as well as process modelling for water filtration plants.

Coralie Gabus | Coralie Gabus is currently working as a Senior Operations Engineer in Customer Delivery (Water Supply & Product) in Sydney Water. She manages the day-to-day selection of raw water for Sydney’s main water treatment plants. She had previously worked as a Process Engineer and was involved in innovative pilot and prototype scale treatments of deteriorated raw water quality to help selection of treatment technologies and optimisation of drinking water process. She has been working for over ten years at Sydney Water on different streams, from odour and corrosion strategy to drinking water process optimisation. She has a degree in Bachelor in Biology and a Master in Environmental Science.

Phoebe Lingat | Phoebe Lingat is a Process Engineer in Water Supply & Production at Sydney Water with 5 years of engineering experience in the drinking water and recycled water industries. She currently coordinates compliance activities for Warragamba Chlorination Plant, a Major Hazard Facility, and provides technical support to optimise current and new water treatment processes. She has previously operated and maintained pilot water filtration plants and worked to ensure the accuracy and reliability of water quality monitoring instruments across treatment facilities. She has a bachelor’s degree in Chemical Engineering and a master’s degree in Biomedical Engineering.