Evaluation of electrochemical disinfection in drinking water networks: A case study on eBooster™ technology

Abstract

Ensuring microbial safety in drinking water distribution networks is a major challenge, particularly in healthcare facilities where waterborne pathogens pose serious risks. Traditional disinfection methods, such as chemical dosing with hypochlorite or in-line ozone treatment, face logistical, economic, and environmental limitations. This paper evaluates eBooster™, an electrochemical disinfection technology developed by Ecas4 Australia, as an effective and low-maintenance method for microbial control in drinking water networks. The proposed electrochlorination system leverages periodic polarity reversal to prevent electrode fouling, enabling continuous operation without external intervention. Deployed in regional and rural hospitals in Queensland, Australia, the system has demonstrated consistent chlorine generation for microbial control with minimal energy consumption (~0.04 kWh/m3).

Performance data from Dalby Hospital, where two eBooster™ systems were installed in an in-line configuration, show its adaptability to fluctuating flow rates and cost-effectiveness compared to traditional methods. A comparative analysis indicates that the proposed technology lowers operational costs by roughly 50% compared to hypochlorite dosing and 98% compared to ozone-based electrochemical systems, while also eliminating challenges with chemical handling and storage. Performance may vary in low-chloride waters or over extended periods, warranting further study. Overall, electrochemical disinfection shows promise in reducing chemical handling and energy use in water disinfection, with potential for further optimisation. Future research will focus on adapting the system for different water compositions and expanding its integration with real-time monitoring technologies.

Introduction

Access to safe drinking water is a global priority, yet disinfection of water and distribution networks remains a challenge, particularly in healthcare settings where vulnerable populations are at risk (Ferro 2025). This study presents the eBooster™ electrochemical disinfection system, building on earlier research (Ferro et al. 2025), with a focus on its sustainability, minimal-maintenance design, and broader applications for improved water safety.

Traditional disinfection methods, like chlorination, UV treatment, and in-line ozonation, are limited by high operational costs, chemical instability, and maintenance requirements (Hand & Cusick 2021). Electrochemical disinfection offers a promising alternative, generating disinfectants on-site without the need for chemical storage or frequent maintenance (Martinez-Huitle & Brillas 2008).

Ecas4 Australia’s electrochemical disinfection systems improve on earlier technology, like the German Aquades-EL, which required regular maintenance due to scale build-up (Kraft 2008; Kraft 2024). Ecas4’s specially coated electrodes support periodic polarity reversal, helping maintain performance in water with moderate levels of calcium and magnesium ions. Long-term performance in diverse water chemistries requires further evaluation. The system’s deployment in Queensland hospitals provides a real-world case study of its efficacy, scalability, and economic viability.

This paper examines the technical, operational, and economic aspects of the eBooster™ system, focusing on its implementation at Dalby Hospital. It also compares in-line electrochlorination with traditional disinfection methods, highlighting its benefits in energy efficiency, operational cost savings, and environmental sustainability.

Background and literature review

Electrochemical disinfection mechanisms

Electrochemical disinfection operates by generating oxidising agents through the application of an electric current to water. This process involves two primary mechanisms: direct and indirect oxidation. In direct oxidation, microorganisms are inactivated when they come close to the anode surface, as electron transfer reactions disrupt the functional groups in microbial cell membranes, causing lipid peroxidation and eventual cell lysis (Li et al. 2025). Efficiency depends on factors such as current density and residence time within the electrochemical cell (Martinez-Huitle & Brillas 2008).

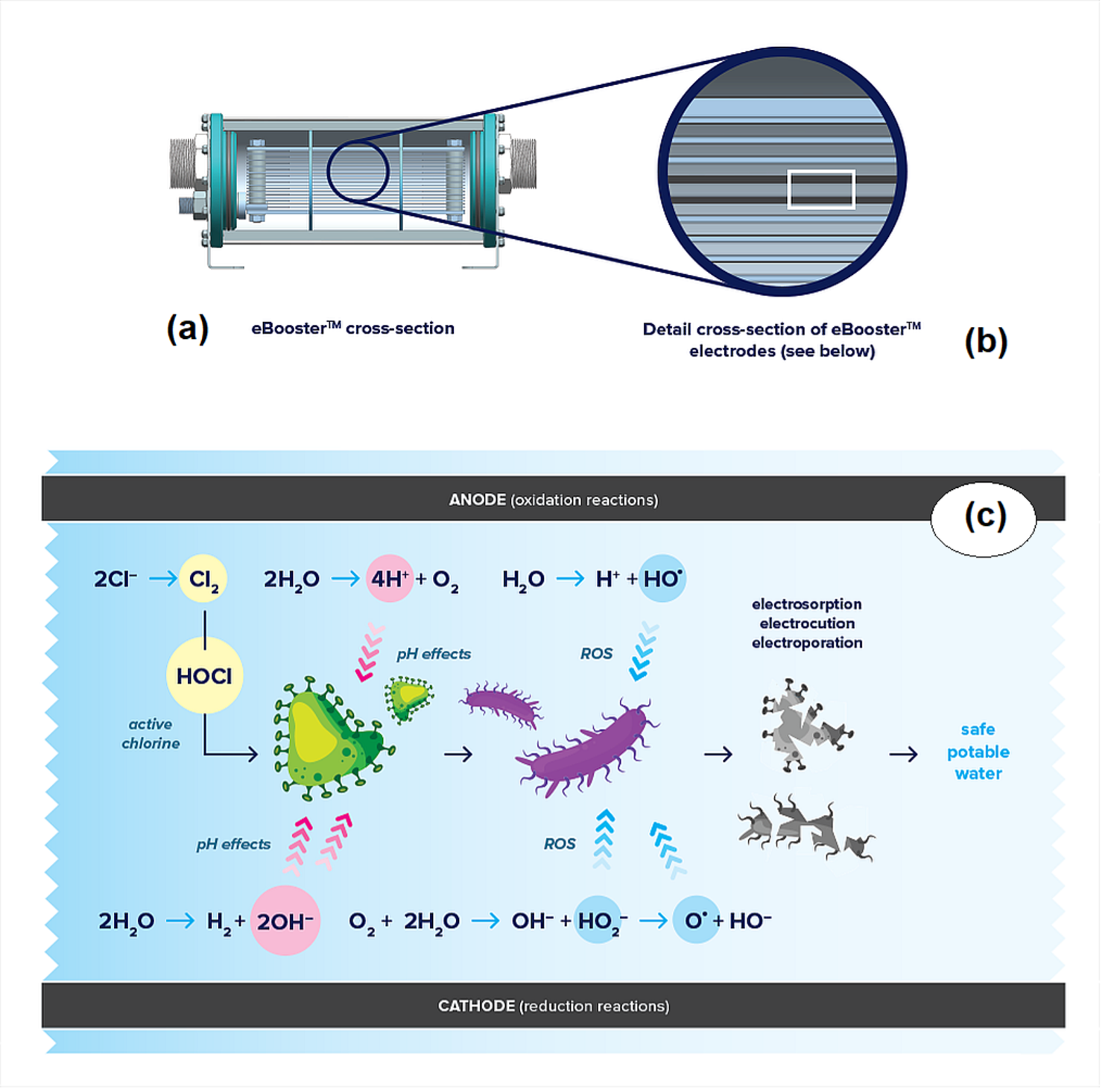

Indirect oxidation, on the other hand, relies on generating reactive species in the bulk solution. In the presence of chloride ions, these are oxidised at the anode to form active chlorine species, primarily hypochlorous acid (HOCl), which provides residual disinfection downstream (Neodo et al. 2012). This dual mechanism (see Figure 1) enables both immediate microbial inactivation and sustained disinfection across the distribution network. Ecas4 Australia’s system capitalises on this by optimising electrode materials, reactor design, and operational parameters to maximise oxidant yield while minimising energy consumption (Ferro 2025).

Figure 1: Key reactions occurring at the electrodes and in solution (in the interelectrode space) within the electrochemical device. (a) Cross-sectional diagram of the device; (b) close-up of an interelectrode section; (c) further detailed close-up of the interelectrode section, with indications of the (electro)chemical reactions occurring.

Limitations of conventional disinfection methods

Traditional water disinfection methods face operational and economic challenges that limit their suitability for long-term use, particularly in remote or resource-constrained settings. Chemical dosing with sodium hypochlorite, while widely used, requires regular replenishment of reagents. Hypochlorite solutions degrade over time, especially with heat or sunlight, necessitating frequent deliveries and secure storage (European Chemicals Agency 2023). In regional hospitals like Dalby, where water meters are housed in outdoor sheds, environmental exposure worsens these issues, increasing chemical degradation and inconsistent dosing.

Ozone-based systems are effective for immediate microbial inactivation but have two major drawbacks. First, ozone lacks a residual disinfectant effect. Second, in-line electrochemical ozone generation is energy-intensive, with systems like Condiapure® consuming around 11.4 Wh per milligram of ozone produced (Rodriguez-Pena et al. 2022). For a facility like Dalby Hospital, this results in an energy cost of ~2.28 kWh/m3 when dosing just 0.2 mg/L (Ferro et al, 2025), making ozone economically unfavourable compared to other electrochemical alternatives. Additionally, its corrosivity requires specialised piping materials, increasing both capital and maintenance costs (Sato et al. 1982).

UV disinfection is chemical-free but provides no residual protection and may become ineffective in turbid water, where suspended particles shield pathogens from UV exposure (Demir et al. 2024). Additionally, UV systems require periodic lamp replacement and quartz sleeve cleaning, increasing operational complexity.

Chlorine dioxide (ClO₂) is effective but unstable, requiring on-site generation due to its short shelf life. It demands precise dosing and pH control, making it resource-intensive and complex. Improper dosing can produce harmful byproducts like chlorite and chlorate, posing health risks (WHO 2016). In remote areas, these challenges, along with the need for constant maintenance, make it less practical than simpler methods like chlorination.

Hydrogen peroxide (H₂O₂) is a strong oxidiser but provides no residual protection, requiring frequent dosing to prevent microbial re-contamination, making it unsuitable for long-term microbial control (Sammarro Silva & Sabogal-Paz 2022). Its on-site synthesis also typically requires softened or deionised water to avoid interference from mineral ions.

Sanitisation with copper and silver ions is effective but requires expensive, specialised equipment and constant monitoring (LeChevallier 2023). Low ion levels reduce effectiveness, while high levels pose health risks. The method is slower than chlorine or UV and ineffective against certain pathogens, like viruses (Kim et al. 2002). Long-term ion accumulation also raises environmental concerns, making this approach less practical in resource-limited areas where rapid disinfection is needed.

While each alternative to (electro)chlorination offers benefits, they all come with operational, logistical, and safety challenges that must be weighed against traditional or more modern disinfection technologies. These limitations highlight the need for alternatives that combine the residual benefits of chlorination with the operational simplicity of electrochemical treatment.

Evolution of electrochemical disinfection technologies

The development of electrochemical disinfection systems has seen iterative improvements to address fouling and scalability. Early systems like the German Aquades-EL, introduced in 1998, used periodic polarity reversal to mitigate scale formation (Kraft 2008) but still required acid washing every few weeks of operation in hard water conditions, leading to high maintenance costs and eventual discontinuation (Kraft 2024). Further details are available in our parent publication (Ferro et al. 2025). Later advancements focused on electrode materials, with dimensionally stable anodes (DSA) and catalytic coatings offering greater resistance to fouling and degradation (Jin et al. 2021).

eBooster™ represents a significant advancement in these efforts, with its proprietary electrode coating that withstands polarity reversal and prevents harmful substance leaching, ensuring compliance with strict drinking water safety standards (Ferro 2025). Field data from Queensland hospitals and an aged-care facility in South Australia show the system can operate for extended periods (two and four years, respectively, so far) without the need for electrode cleaning (Ferro et al. 2025), a milestone not achievable by earlier technologies. This reliability, combined with IoT-enabled monitoring, makes electrochemical disinfection a viable solution for decentralised and small-scale applications.

Materials and methods

System design and operational framework

Ecas4 Australia’s approach to in-line electrochlorination is based on two main components: the electrochemical device and the control panel, which work together to deliver consistent disinfection performance.

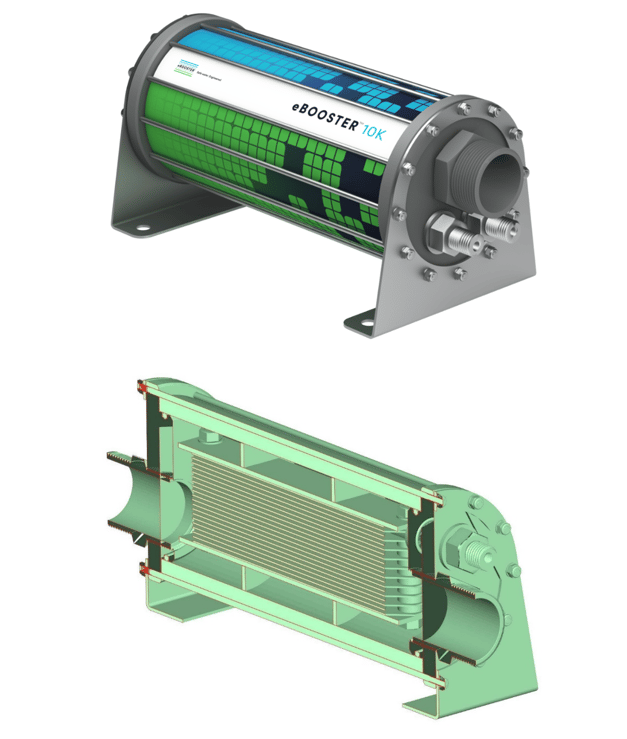

The electrochemical device (Figure 2) features a series of planar electrodes arranged in an interdigitated configuration, providing a total anode surface area of approximately 1.3 m² in the B10k models deployed at Dalby Hospital. These electrodes employ a proprietary coating specifically formulated to withstand the stress of periodic polarity reversal while maintaining catalytic activity for chlorine generation. The coating composition has demonstrated to resist degradation even in water with moderate to high hardness levels, addressing a critical limitation of earlier electrochemical systems.

Figure 2: (a) Ecas4 Australia’s eBooster™ model B10k, rated for peak flow rates up to 800 L/min under tested conditions. Dimensions: 320 × 280 × 510 mm; Weight: 19 kg; maximum working pressure: 20 bar (2000 kPa); materials: uPVC (food grade) and Titanium. (b) 3D cross-section showing the internal electrode stack and the presence of barriers to prevent water from flowing out of the interelectrode space, bypassing the treatment.

The control system architecture represents a sophisticated integration of hardware and software components. At its core, an ESP32 System-on-Chip processor manages all operational parameters through custom firmware. This IoT-enabled platform facilitates real-time monitoring and control through two distinct interfaces: a cloud-based WebApp for remote management and a direct Wi-Fi access point for local configuration. The system’s adaptive algorithm dynamically adjusts current output in response to flow rate variations, ensuring a relatively stable chlorine production across the hospital’s variable demand profile.

Installation configuration and hydraulic considerations

In mid-2023, two B10k units were installed in an in-line configuration at the separate water meters serving different sections of the Dalby Hospital facility. The primary unit, located at the Swan Street meter, serves most of the hospital and was designed to accommodate peak flows of 10 L/s (600 L/min), while the secondary unit, at the Hospital Road meter, delivers water primarily to the maternity ward and is sized for a capacity of 6 L/s (360 L/min).

To ensure operational reliability and maintenance accessibility, each unit was installed within a uPVC bypass line with full-bore isolation valves, enabling maintenance without interrupting the hospital water supply. The electrochemical devices were oriented vertically to facilitate gas venting, as electrolysis generates current-dependent volumes of hydrogen and oxygen that could otherwise accumulate, disrupting flow or masking portions of the electrodes. Downstream gas release valves were added at high points in the pipeline to prevent gas build-up, particularly at low-flow rates.

Operating a variable flow system requires initial calibration to determine the current needed for the desired active chlorine level under different flow conditions. Periodic recalibration is suggested to account for changes in water quality (e.g., chemical or temperature variations, often due to seasonal shifts). As residual chlorine effectively cleans the downstream distribution network, its chlorine demand may decrease over time, requiring recalibration to prevent excess chlorine.

The installation, managed and completed by Aquastream Water Solutions (Toowoomba, QLD), included an electromagnetic flow sensor (Siemens MAG 5100 W) upstream of each unit and flow control mechanisms to prevent dry running, a critical safeguard given the system’s reliance on water as both a coolant and an electrolyte.

Performance monitoring and data acquisition

The system’s performance was monitored via a data acquisition framework. The DIN-rail-mounted controllers were programmed to transmit telemetry data to the cloud every 30 minutes, capturing key parameters such as flow rate, applied current, and cell potential. This dataset enabled detailed analysis of the system’s response to the hospital’s daily and seasonal demand patterns.

At the Hospital Road installation, additional monitoring was provided by a Lutz-Jesco Topax L1 amperometric chlorine analyser, offering continuous measurement of residual chlorine levels downstream of the treatment unit. Although the chlorine sensor was not integrated into the control loop, its data validated the system’s disinfectant production, despite the need for periodic recalibration of the probe.

Analysis of the collected data considered several operational realities. While the 30-minute sampling interval was sufficient for trend analysis, transient flow events of shorter duration may not have been fully captured. However, the hospital’s water usage patterns, characterised by prolonged low-flow periods and occasional high-demand events, were adequately handled by the system. The system’s firmware also incorporates data smoothing algorithms to prevent instability from short-term flow fluctuations.

Safety and compliance considerations

The implementation met the stringent safety and regulatory standards required for healthcare water systems. All wetted components were either WaterMark “Lead Free” certified (WaterMark Certification Scheme 2016) or at least compliant with AS/NZS 4020:2018 for materials in contact with drinking water (Standards Australia 2018). The electrochemical units are rated for a nominal pressure of 20 bar, significantly exceeding the hospital’s distribution system pressure.

Electrical safety measures included ground fault protection on all power supplies and isolation transformers for the control circuits. The 12V DC operating voltage of the electrochemical cells was deliberately chosen to minimise risks associated with higher voltage systems while still providing sufficient overpotential for the desired electrode reactions.

It is also worth noting that, although another product/brand is currently marketed in Australia, it is not WaterMark certified and its installation may (depending on the application) constitute a regulatory violation for the plumber performing the work. Furthermore, comparative tests conducted in September 2021 showed that the product that is the subject of this paper produced 20% more free available chlorine while consuming 30% less energy than the other product on the Australian market.

Results and discussion

Operational performance and microbial inactivation efficacy

The eBooster™ systems demonstrated consistent performance over the two-year monitoring period at Dalby Hospital, supporting their design objectives for reliability and effectiveness under real-world conditions. Performance may vary in waters with high turbidity, extreme pH, or variable chloride levels, and could also be affected by periodic recalibration requirements. Additionally, data may reflect uncertainties due to short-term flow variations. Analysis of the telemetry data revealed several key operational patterns that underscore the system’s technical merits.

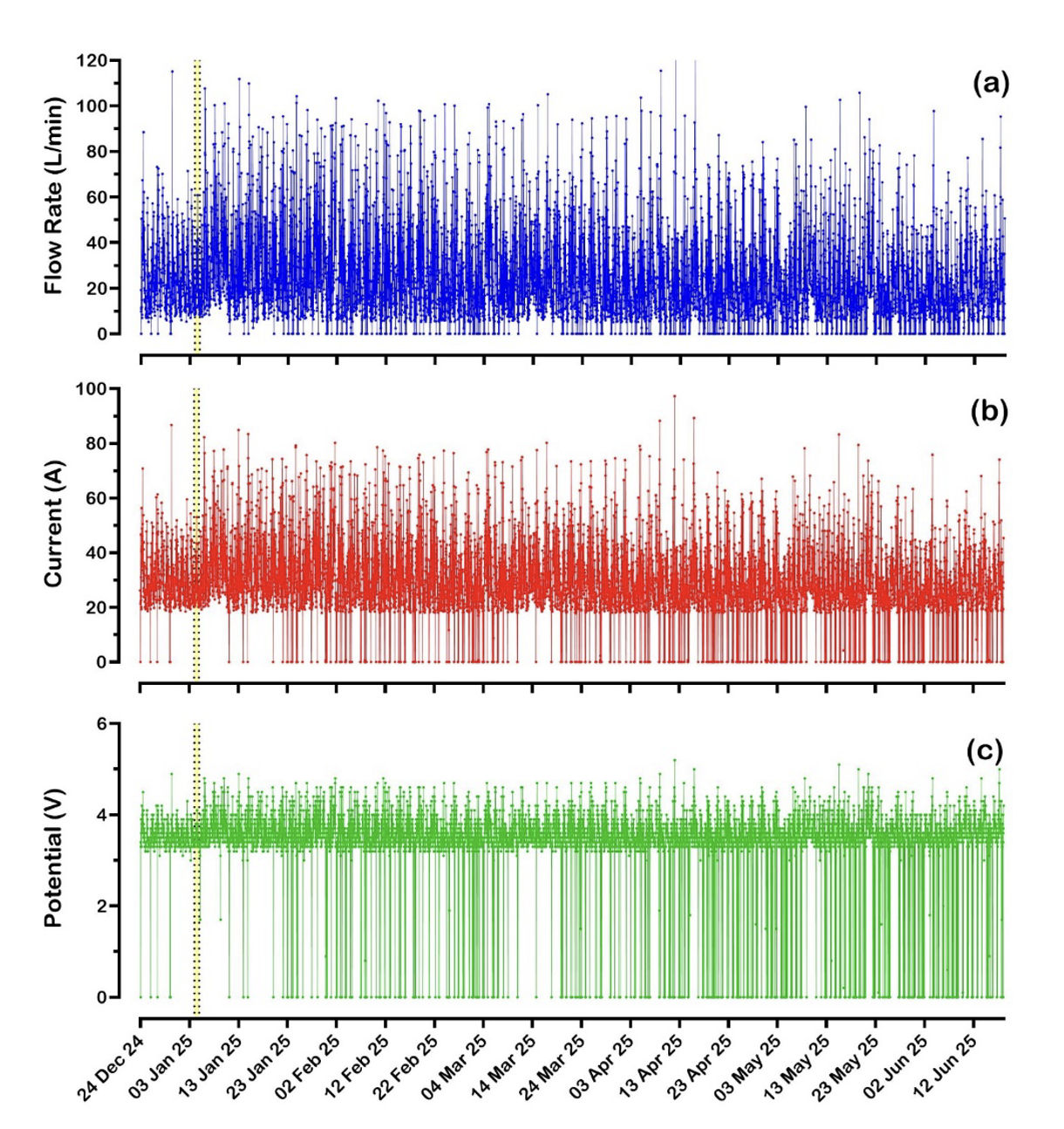

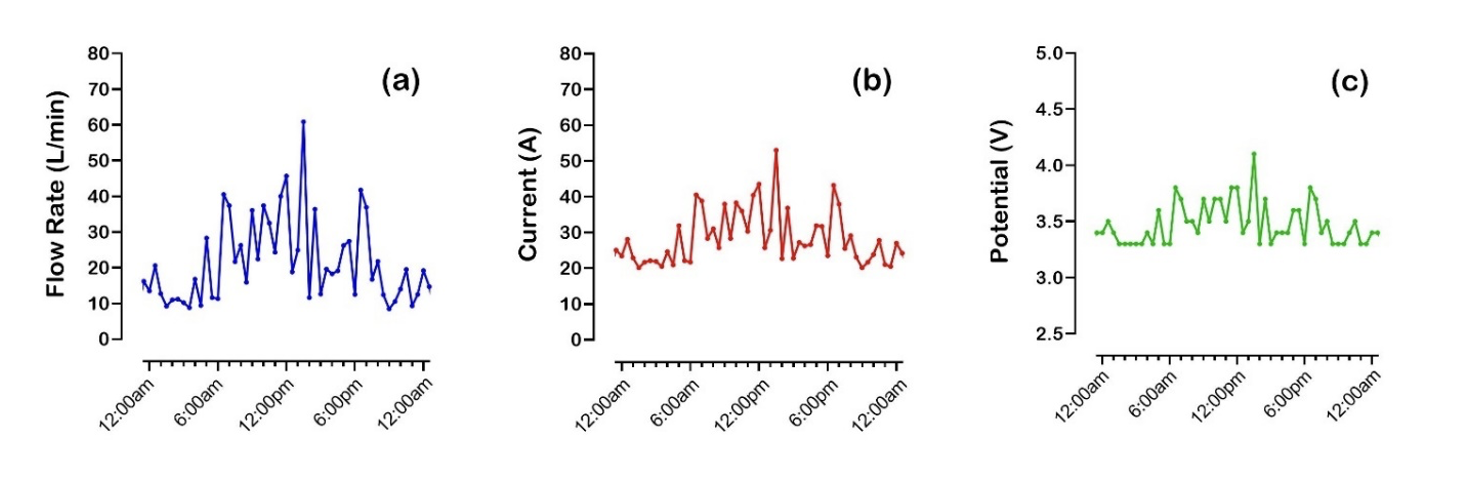

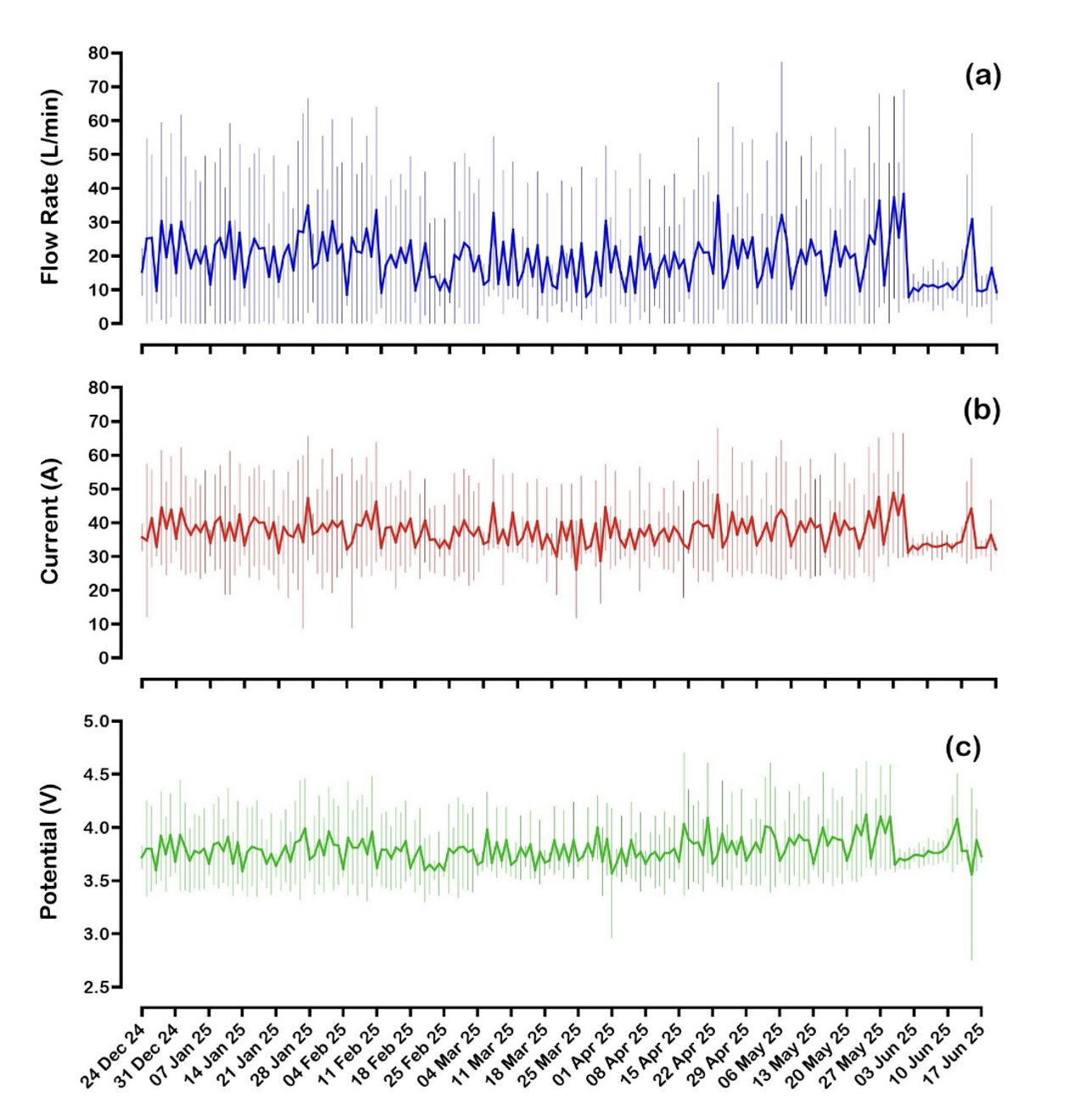

The primary unit installed at the Swan Street water meter processed an average flow rate of 27 ± 5 L/min, with a peak demand of 120 L/min (Figures 3–5). The system’s adaptive current control algorithm effectively maintained chlorine production across this dynamic range by modulating the output current from 0 to 90 A in direct correlation with flow rate changes. This responsiveness ensured a relatively stable disinfectant level, avoiding the overdosing common in many conventional dosing systems. The corresponding cell potential remained below 5 V, even at maximum current, reflecting the system’s energy-efficient design and the stable overpotential characteristics of the electrodes.

Figure 3: Trends of (a) flow rate, (b) current, and (c) potential over 6 months for the system installed at the main flow meter (off Swan Street) at Dalby Hospital.

Figure 4: Example of raw data acquired in one day (3 January 2025): (a) flow, (b) current and (c) potential. Data are extracted from Figure 3 and refer to the time interval shaded in yellow.

Figure 5: Daily averages and standard deviation values derived from Figure 3, with near-zero values excluded from the analysis.

Microbial inactivation performance was validated through both laboratory studies and field observations. Controlled tests at the University of South Australia demonstrated high efficacy against Pseudomonas aeruginosa, achieving a 5.37 Log reduction (99.99966% inactivation) in water with a chloride concentration of 355 mg/L (Ogunniyi & Dandie 2019). These laboratory conditions represented an upper-bound scenario; the actual performance at Dalby Hospital, with lower chloride levels (~120 mg/L), would likely fall between this result and the 1.14 Log reduction observed in chloride-free tests (Ogunniyi & Dandie 2019).

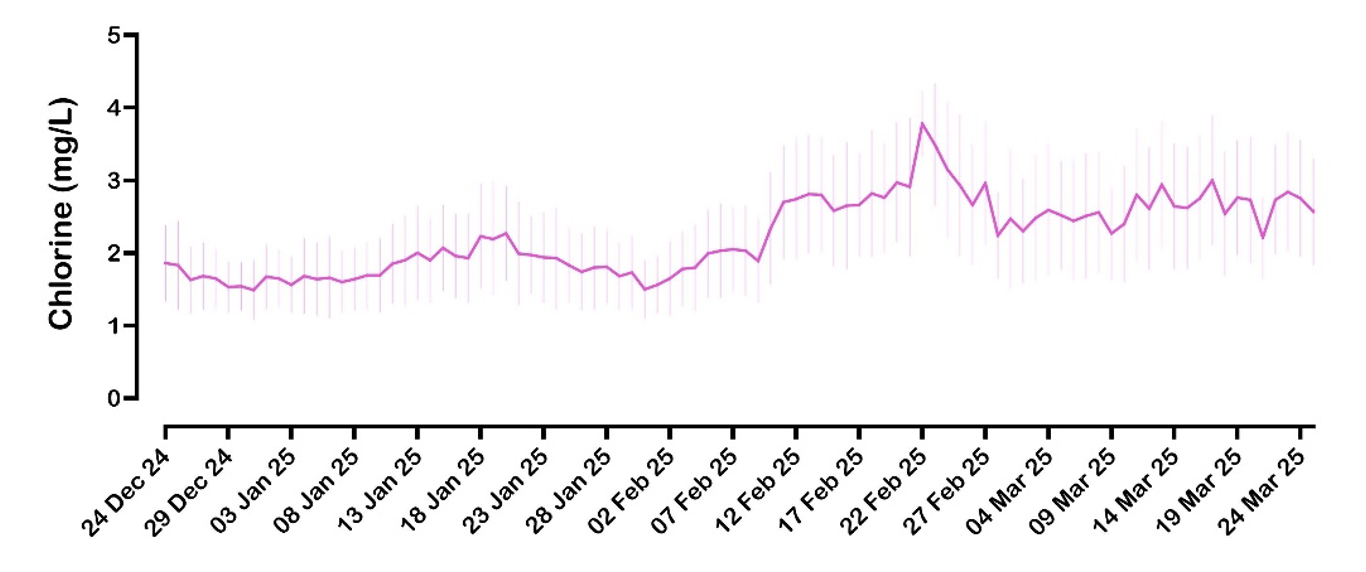

Field measurements of residual chlorine consistently maintained levels around 1.5 mg/L at treatment points, sufficient for effective microbial control while remaining below thresholds for taste complaints or excessive disinfection byproduct formation. Remote monitoring with the amperometric chlorine analyser, installed downstream from the Hospital Road meter, showed residual chlorine levels gradually rising from the target setpoint of 1.5 mg/L to an average of nearly 3 mg/L (Figure 6). Since the hospital conducts weekly tests and hasn’t requested adjustments from Aquastream Water Solutions, the chlorine drift is likely due to the need for recalibration of the chlorine probe. Further details can be found in our parent publication (Ferro et al. 2025).

Figure 6. Trends of daily average residual chlorine and standard deviation over 3 months for the system installed at the second flow meter (near Hospital Road) at Dalby Hospital.

Long-term stability and maintenance reduction

The installed systems have operated continuously for a couple of years (to date) without requiring cleaning or electrode replacement, despite handling hard water (see Table 1). This maintenance-free performance marks an improvement over previous electrochemical disinfection technology. For comparison, the Aquades-EL system, as discussed earlier, typically required acid washing every 4–12 weeks, depending on water hardness, and full electrode stack replacement every 12–18 months (Kraft 2024). UV disinfection also requires lamp replacement at a similar frequency. In a separate case (warm water treatment in a loop at an aged-care facility in Klemzig, South Australia), an eBooster™ system was installed in April 2021 and has been operating ever since, with only periodic recalibration of the chlorine probe for maintenance.

Table 1. Water quality values extracted from the Council’s Drinking Water Quality Management Plan Annual Report; Period July 2023 – June 2024 (Western Downs Regional Council 2025, pp. 74-75).

| Parameter | Average Value | Min Value | Max Value |

| Calcium (mg/L) | 26.10 | 15.00 | 60.00 |

| Chloride (mg/L) | 142.65 | 30.00 | 250.00 |

| Conductivity (µS/cm) | 889.00 | 320.00 | 1300.00 |

| Magnesium (mg/L) | 24.35 | 13.00 | 65.00 |

| pH | 7.86 | 7.15 | 8.52 |

| Silica (mg/L SiO2) | 15.98 | 2.00 | 23.00 |

| Total Hardness (mg/L CaCO3) | 165.43 | 92.00 | 418.00 |

The performance of Ecas4 Australia’s technology can be attributed to three key design factors: first, the proprietary DSA coating formulation provides high resistance to both chemical degradation and scale accumulation. Second, the polarity reversal protocol effectively prevents the build-up of calcareous deposits that affect conventional systems. Third, the system’s hydraulic design ensures uniform flow distribution across all electrode surfaces, preventing localised scaling or fouling hotspots.

This reliability translated into operational benefits for the hospital. While traditional hypochlorite systems require weekly chemical deliveries and monthly maintenance checks, the proposed in-line electrochemical disinfection operated substantially unattended. The elimination of chemical handling also removed associated occupational health and safety risks, particularly important in a healthcare setting.

Energy efficiency and operating cost performance

The system’s energy consumption metrics revealed exceptional efficiency, both in absolute and comparative terms. The primary unit installed at the Swan Street water meter consumed an average of 540 Ah per day (29.4 A at 3.3 V for 18.4 h/day), equating to 1.8 kWh of daily energy consumption. With a daily water demand of ~41 kL, this results in an energy use of about 0.044 kWh/m3. At commercial electricity rates (AUD 0.40/kWh), the daily operating cost is just AUD 0.70. The secondary unit, serving lower flow rates (averaging 18.9 L/min when water is required, or 11.7 kL/day), consumed only 185 Ah per day, i.e. approximately 700 Wh (AUD 0.30) or around 0.042 kWh/m3.

A comparative analysis of alternative disinfection methods highlighted the cost competitiveness of the proposed technology. Achieving equivalent protection with hypochlorite dosing would cost approximately AUD 2.00 per day in chemical costs alone (based on a 15L container priced at $27.60 from a local Bunnings Warehouse), excluding labour, transportation, and storage expenses (Ferro et al. 2025). In-line ozone generation, requiring around 125 kWh/day for similar disinfection capacity (Rodriguez-Pena et al. 2022), would incur about AUD 50 per day in energy costs when dosed at 0.2 mg/L (~2.28 kWh/m3) – substantially higher than the eBooster™ electrochemical system (Ferro et al. 2025). However, ozone may be more suitable for certain contaminants, particularly organic compounds.

These operating cost differentials become particularly significant when projected over the system’s expected service life of over 10 years, based on current operating conditions at Dalby. The economic advantage is further amplified in remote areas, where chemical transportation costs can nearly double the price of hypochlorite.

Technological and societal impact assessment

Advances in water treatment paradigms

The implementation of in-line electrochlorination at Dalby Hospital, and other facilities in Queensland and South Australia, marks a significant advancement in water disinfection practices, combining operational simplicity with effective microbial control. Data from Dalby Hospital show that sustained disinfection is achievable with minimal maintenance, offering a practical approach for critical environments.

This is especially significant in healthcare settings, where waterborne infections contribute to around 10% of hospital-acquired illnesses globally, disproportionately affecting vulnerable patients (Anaissie et al. 2002). Traditional chemical dosing systems, with their variable disinfectant levels and reliance on external supply chains, have struggled to manage this risk consistently. The ability to maintain relatively stable chlorine residuals under variable flow conditions may help reduce this burden, particularly in critical areas like intensive care.

Regulatory and standardisation considerations

The performance of in-line electrochemical systems raises questions about the adequacy of current regulatory frameworks, which are primarily designed around conventional dosing technologies. Revised standards may be required to assess maintenance-free electrochemical disinfection, with attention to long-term electrode stability, reliable disinfectant production, and consistent performance across varying water qualities and operational patterns.

Global health implications

In resource-limited settings, where healthcare-associated infections contribute to significant morbidity and prolonged hospital stays (WHO 2011), affordable and reliable disinfection technologies can have a major impact. Systems with minimal infrastructure and maintenance needs may be particularly well suited to such environments, where conventional methods are often impractical.

Knowledge gaps and research needs

Several questions remain about the long-term performance and broader applicability of the technology. While evidence from four years of operation in a warm water loop in South Australia is promising, additional data beyond the current two-year observation period at Dalby is needed to assess electrode durability. Accelerated laboratory testing could provide insights into decade-scale performance. Research into operator interaction and system interface design is also critical as automation and data analytics become more common. Furthermore, studies on institutional and behavioural barriers to adoption could help shape strategies for broader implementation.

Conclusion and future perspectives

Summary of findings

Evaluation of the systems at Dalby Hospital shows that maintenance-free electrochemical disinfection can be sustained over extended periods while maintaining microbial safety. This is achieved through advanced electrode design, flow-adaptive control, and continuous monitoring. Cost analysis indicates lower operating expenses compared to traditional hypochlorite dosing and (in-line) ozone-based methods, while avoiding the hazards of chemical handling.

Implications for practice

This approach may be particularly relevant in settings with limited technical support, where maintaining residual disinfection across a distribution network is critical. It also supports broader sustainability objectives by reducing chemical usage, lowering energy consumption, and cutting greenhouse gas emissions.

Future research directions

Further investigation is needed to assess the system’s effectiveness against chlorine-resistant microorganisms, its performance in low-chloride waters (<50 mg/L), and its scalability for larger municipal networks (e.g. treatment of over 100 L/s; this proposed “limit” is based on water quality and the number of devices required to treat the necessary volume, assuming each device can handle up to 10 L/s. It would likely be easier to increase the size of each individual device rather than using multiple units). Exploring alternative electrode materials could improve efficiency, reduce costs, and extend system lifespan.

Broader adoption potential

Findings from Dalby suggest these systems could extend beyond healthcare, with potential applications in remote communities, maritime environments, food processing, and small municipal water networks. The modular design allows for adaptation to different scales and settings, potentially enhancing resilience against supply disruptions, climate variability, and aging infrastructure.

Final observations

The integration of electrochemical engineering, materials science, and digital monitoring at Dalby Hospital illustrates how maintenance demands and operational risks in water disinfection can be reduced. While further research is needed to assess performance under varying conditions and over longer timescales, the findings highlight a promising alternative to conventional chemical-based approaches, with potential benefits in both safety and sustainability.

Acknowledgements

The authors greatly acknowledge the support and assistance of Aquastream Water Solutions.

The Authors

Sergio Ferro

Sergio is a chemical scientist with nearly 30 years of expertise in electrochemical reactivity, materials chemistry, and environmental science. After earning a PhD in 2002, he led R&D at the University of Ferrara before moving to Australia. As Technical Manager at Ecas4 Australia, he focuses on sustainable electrochemical solutions.

Daniel Vallelonga

Daniel has played a key role in the research and development of in-line water treatment systems and advanced technologies. His work supports Ecas4 Australia’s mission to deliver innovative solutions that enhance sustainable water quality, improve efficiency, and create a positive environmental impact across various industries.

Daniel Romeo

Daniel worked as the Executive Manager of Ecas4 Australia for 5 years, leading strategic initiatives and operations to drive growth. Focused on sustainable water treatment, he advanced technologies to improve water quality and environmental impact. Since June 2023, he has been an Executive Director for the Government of South Australia, collaborating on key projects and policy reforms.

Basil Mondello

Since 2010, Basil has specialised in the water treatment industry, focusing on research and development, prototype design, and the maintenance of water treatment equipment. His expertise has contributed to the advancement of efficient and sustainable water solutions, ensuring optimal performance and reliability across various systems.

Gusius Gus

Gusius, Doctor of Engineering, is a leading expert at Milspec Research International, specialising in advanced engineering solutions and cutting-edge technologies. He drives innovation and research to meet high-performance standards across various industries.

Paul Caruso

Paul is the Director of 101Electrical, founded in 2012. With a strong engineering background, he leads the company in delivering innovative electrical and IT solutions across South Australia. Specialising in large-scale projects, 101Electrical ensures high-quality execution, client satisfaction, and future-ready infrastructure for diverse sectors.

Tony Amorico

Tony is the Director of Ecas4 Australia, a company specialising in innovative, eco-friendly sanitisation solutions for the health and food sectors. Under his leadership, the company is advancing its eBooster™ technology, designed to improve sanitation processes and enhance safety and efficiency across these critical industries.

References

Anaissie, E J, Penzak, S R, Dignani, M C, 2002. The hospital water supply as a source of nosocomial infections: a plea for action, Archives of Internal Medicine, 162(13), pp. 1483–1492.

Demir, M Z, Guven, H, Ersahin, M E, Ozgun, H, Pasaoglu, M E, Koyuncu, I, 2024, Comparative life cycle assessment of four municipal water disinfection methods, Sustainability, 16, p. 6104.

European Chemicals Agency (ECHA) 2023, Registration Dossier: Sodium Hypochlorite, viewed 16 June 2025, https://echa.europa.eu/registration-dossier/-/registered-dossier/15516/5/2/1.

Ferro, S, 2025, Challenges in designing electrochemical disinfection systems for reducing microbial contamination in drinking water distribution networks, Water, 17, p. 754.

Ferro, S, Vallelonga, D, Romeo, D, Mondello, B, Gus, G, Caruso, P, Amorico, T, 2025, Electrochemical disinfection in drinking water networks: A sustainable, maintenance-free solution using eBooster™ technology, Water, 17(9), p. 1361.

Hand, S, Cusick, R D, 2021, Electrochemical disinfection in water and wastewater treatment: Identifying impacts of water quality and operating conditions on performance, Environmental Science & Technology, 55(6), pp. 3470-3482.

Jin, H, Zhang, Y, Zhang, X, Yu, Y, Chen, X, 2021, High-performance Ti/IrO₂-RhOx-Ta₂O₅ electrodes for polarity reversal applications, Industrial & Engineering Chemistry Research, 60(10), pp. 4310-4320.

Kim, B R, Anderson, J E, Mueller, S A, Gaines, W A, Kendall, A M, 2002, Literature review—efficacy of various disinfectants against Legionella in water systems, Water Research, 36(18), pp. 4433-4444.

Kraft, A, 2008, Electrochemical water disinfection: A short review, Platinum Metals Review, 52(3), pp. 177-185.

Kraft, A, 2024, Personal communication, Kraft Consult, Eichwalde, Germany.

LeChevallier, M, 2023, Examining the efficacy of copper-silver ionization for management of Legionella: Recommendations for optimal use, AWWA Water Science, 5(2), e1327.

Li, Y, Zong, Y, Feng, C, Zhao, K, 2025, The role of anode potential in electromicrobiology, Microorganisms, 13, p. 631.

Martinez-Huitle, C A, Brillas, E, 2008, Electrochemical alternatives for drinking water disinfection, Angewandte Chemie International Edition, 47(11), pp. 1998-2005.

Martinez-Huitle, C A, Ferro, S, De Battisti, A, 2005, Electrochemical incineration in the presence of halides, Electrochemical and Solid-State Letters, 8(11), pp. D35-D39.

Mitch, W A, Richardson, S D, Zhang, X, Gonsior, M, 2023, High-molecular-weight by-products of chlorine disinfection, Nature Water, 1, pp. 336-347.

Nathan, C, Cunningham-Bussel, A, 2013, Beyond oxidative stress: An immunologist’s guide to reactive oxygen species, Nature Reviews Immunology, 13, pp. 349-361.

Neodo, S, Rosestolato, D, Ferro, S, De Battisti, A, 2012, On the electrolysis of dilute chloride solutions: Influence of the electrode material on Faradaic efficiency for active chlorine, chlorate and perchlorate, Electrochimica Acta, 80, pp. 282-291.

Ogunniyi, A D, Dandie, C, 2019, Personal communication, Future Industries Institute, University of South Australia.

Queensland Department of Environment and Heritage Protection 2013, Queensland Water Quality Guidelines 2009, Brisbane: Queensland Government.

Rodriguez-Pena, M, Barrios Perez, J A, Lobato, J, Saez, C, Barrera-Diaz, C E, Rodrigo, M A, 2022, Scale-up in PEM electro-ozonizers for the degradation of organics, Separation and Purification Technology, 284, p. 120261.

Sammarro Silva, K J, Sabogal-Paz, L P, 2022, A 10-year critical review on hydrogen peroxide as a disinfectant: could it be an alternative for household water treatment?, Water Supply, 22(12), pp. 8527-8539.

Sato, Y, Suzuki, M, Matsudaira, M, 1982, Dissolved ozone effect on corrosion of metals in water, Boshoku Gijutsu, 31, pp. 319-324.

Standards Australia 2018, Australian/New Zealand

Standard 4020: Testing of products for use in contact with drinking water, Sydney: Standards Australia.

WaterMark Certification Scheme 2016, WMTS-103:2016: Water treatment systems (other than those specified in AS/NZS 3497), Canberra: Australian Building Codes Board.

Western Downs Regional Council 2025, Drinking Water Quality Management Plan (DWQMP), Dalby: WDRC Publications. https://www.wdrc.qld.gov.au/Services-Payments/Utilities/Water#section-6

World Health Organization 2011. Burden of endemic health care‑associated infection worldwide: modelled analysis. Geneva: WHO. https://iris.who.int/bitstream/handle/10665/80135/9789241501507_eng.pdf

World Health Organization 2016. Chlorine dioxide, chlorite and chlorate in drinking-water: background document for development of WHO guidelines for drinking-water quality. Geneva: WHO.

https://www.who.int/docs/default-source/wash-documents/wash-chemicals/chlorine-dioxide-chlorite-chlorate-background-document.pdf